failed my eddie current instpection

Just to share, I have a pa28-151...6735hrs on it but with a missing log book. My right wing forward bolt hole failed the inspection. We then removed the wing and reinspected it just to be sure, and it failed once again. Wing is now in Indiana getting the spar replaced.

The tech has pointed out that flight time has very little to do with the passes vs failures and would expect the FAA to change that flight time based on the info they get. For example my tech passed a 18k and 21k hr aircraft, but has failed 4 now with less then 7k.

Im glad I got the test done and even if your aircraft does not meet the time requirements, I would consider getting it done anyway. Its not intrusive at all and if you pull your own interior out yourself it costs less then 1k bucks.

If you have any questions...shoot away..I m here to help..

slo

Comments

Thanks SO MUCH for the update. This is good to know and very much appreciated.

Scott Sherer

Wright Brothers Master Pilot, FAA Commercial Pilot

What was the "factored hours" for your pa28-151?

Any thought on the factors that did cause the failures in yours or the others? Corrosion? Stress? Other factors? It's quite interesting that some high time spars pass when some lower time did not. Any differences in thickness of original parts specs by chance?

Jim

It could be as simple as how dull the drill bit was when it was manufactured or how they deburred it. Holes that have design marginality will have a wide range of good to bad due to variations in manufacturing. Based on the examples so far I think it is possible this AD could be expanded to straight hours vs factored hours.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

I will share all I can, however Scott if you are going to print this in the magazine please remove my name from it....thanks

I do not know the factored hours since I am missing a log book, but like I said it has just over 6700 hrs and spent most of its life as a trainer.

What's causing it?? Well the tech that did mine has noticed a few things...location seems to play a big part, near the ocean and you have a much higher chance of failure...Note that mine has spent its life in the midwest...grrr... Second is damage history according to the tech. Again mine has no damage history as far as we know...missing logbook and all. But to me the scariest thing and the thing that will be hardest for the FAA, is their seems to be no other rhyme or reason....if the airplane has had X amount of hard landings, you will have a crack. The tech was very certain though that TT has very very little to do with if you have a crack or not....That will be hard for the FAA to deal with IMHO.

Personally after having one wing fail I firmly believe that this will become a repeating inspection.

Message received

Scott Sherer

Wright Brothers Master Pilot, FAA Commercial Pilot

This is from another chat, so take it for what its worth....

Yesterday at 6:55 PM

Add bookmark

142

I just spent 45 minutes on the phone with Airframe Components who helped advise the FAA and NTSB on this AD and the news from the fleet so far is NOT good. They expect the FAA to expand this to exponentially one way or another to include all Pipers that could have this issue or something to that effect. They said the Warrior and Archer numbers they are seeing failed are way higher than had been predicted. Including voluntary AD inspections that did not meet the hour requirement to have it apply.

They also said Piper is way behind trying to spool up to make Spars and for example the 32R-300 is over a year and a half to get one.

I am wondering how many are failing the test due to manufacturing issues versus a legitimate crack in the spar due the excessive strain. Part of me thinks that way more wings would be falling off the fleet from various maneuvers if this was such a widespread problem.

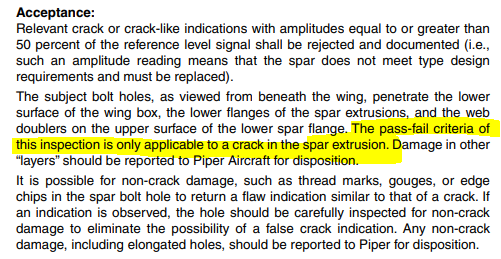

This whole AD is unusual with "factored hours" but no clear explanation of why those hours are so unfavorable vs regular hours. It is also worth noting that a fail must be in the spar extrusion.

It would seem possible to have an AMOC that would match drill the hole larger for a custom close tolerance bolt and retest. If I understand the acceptance and crack criteria we are talking about a .015 inch crack (0.38 mm). I am not sure if you should be more alarmed that it has cracked more than 0.38 mm or that it could be just less than 0.38 and be ok...

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Would like to save other owners some time by recommending CTC Services Inc. out of Lincoln, CA for this eddy current inspection since NDT ii/iii inspectors are very difficult to come by. They're mobile, and willing to travel to other states to perform the inspection. It took me days to find someone since my plane was already down and opened up for its annual at the time of AD publication, so I didn't have the luxury of planning this in advance. Hope this info helps for anyone within a couple hundred miles of Sacramento.

Thanks so much for the recommendation.

Scott Sherer

Wright Brothers Master Pilot, FAA Commercial Pilot

It is worth it to fly experts in for the inspection vs travel anywhere away from your maint home base. If it fails you are grounded on the spot. Best in your hanger or maint shop as the work involved and downtime is extensive.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)