New Rebuilt Factory Engine Issues

First some history, early last year my original engine had chewed up the lifter and cam. Decided after much back and forth to go with a factory “0” time rebuild. Engine was received in June of 2020, and the installation and first flight occurred in September. The engine was installed with all new hoses and hardware. The first startup and flight was done following Lycoming service instruction. Flew for 2.0 hours with a higher then the rest cylinder temp on number 1. This trend has continued through the whole breaking period. Normal high temps are around 420 to 430 degrees during initial climb to 500 feet. Normally at reaching 500 feet you could lower the nose and cool the cylinder off, once cool below 400+ degrees the cylinder would not normally exceed 400 degrees. Also noted during the first 10 hours was hard starting and engine kick back during failed starts. Investigation found that both magnetos were approximately 29 degrees advanced. Adjusted both mags back to 25 degrees and the kick back and hard starting was better. Cylinder#1 continue to still run warm, conversations with Lycoming tech rep stated he was ok with the cylinder temp. He commented the soft limit was 435 degrees. He said he wasn’t worried about but to keep flying it. Fast forward to 42 hours and again the timing was off by 3 degrees? Number 1 cylinder still exceeding 400 degrees during the initial climb. Inspection of the plugs show cylinder #1 is running leaner then the rest. Compressions were performed cold #1 was 78/80 #2 76/80 #3 79/80 & #4 78/80. Talking with Lycoming they requested an induction leak check which is planned for this weekend. If no induction leaks are noted they Lycoming want me to have send the carburetor back to AVSTAR for evaluation. Reviewing the as run data sheet I noticed the mag drops on brand new mags at 124 RPM Drop on both. To me this is a little high, wanted to hear the chats comments to see if I am off base on my concerns. I am seeing at least that much or more currently. In the past I have done inspections and internal timing on magnetos and have never see them this high? After 42 hours I am just not feeling the confidence level I should have for a factory motor? I know this is long, but wanted the folks to have all the information of my issues?

Comments

With a carburetor hard to balance fuel flows. I would run it richer to keep #1 < 400 during climb. EGT's should be ~ 1200-1300 in climb. If they are higher you are likely too lean overall.

What is the oil consumption like?

For cyl #1 I would check baffling including the under cylinder baffles.

The mag drop is very concerning. Mag timing should not slip this quickly and 4 degrees is far over a short period. If it slipped twice that is even more of a concern (7 degrees total). I would insist on having the mags fully overhauled or replaced. Kick back may have damaged the mags or the coupler cushion too.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Oil usage as basically a quart in 15 hours. With the new motor I invested in a set of AIRFORM baffles, I also made sure I had no air gaps.

I feel the same way as you I don’t agree with getting new magnetos out of a box and have roughly 125RPM drop. I have installed new and overhaul units that were around 50 to 75 RPM drops. You can’t even talk to a person at Champion anymore!

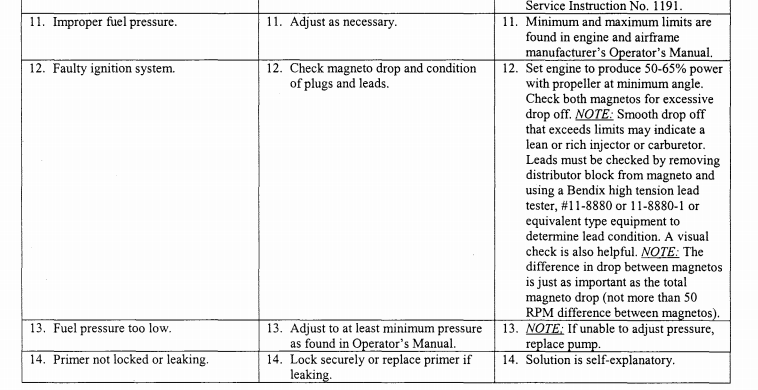

Thanks for the words of wisdom.

I think it is possible to adjust the carb so that it is richer at sea level. If you are climbing out at 1300 EGT it would be a small adjustment if any. I would check carefully on the baffles including the underside baffles as these can easily be over looked.

I am not as worried about the mag drop. The drifting timing concerns me. Should not drift that much over those hours. Either there is a procedure error (which is tough on a lycoming) or there is something internally drifting.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

We purchased brand new Lycoming 0-235L2C Cylinders for our Cessna 152.

The engine runs very hot

Eventually Lycoming told us with the new type of Cylinder wall treatment they have introduced

Higher Temperatures are a possibility.

Dtaglila, sorry to hear you're having this problem. Per the overhaul manual the factory will perform a flow bench calibration on the carburetor, and then a test cell run on the completely-assembled engine before shipping it back to you. Both tests follow a sequence of power and flow settings spelled out in the manual and will generate a bunch of test data that confirms your engine is working as designed before it leaves the engine shop. If you don't have that data already suggest requesting it from the factory, and reviewing it with your A&P. If all that looks good (I've seen several cases where the factory data was a "fail," but they shipped the engine anyway...), and you have an engine monitor, you'll be able to repeat most of the test run on the ground and compare the factory data with what you're getting in the field. Good luck! Bob T.

You are right to hold your ground. High temps in an air cooled engine are generally broken down into a few categories:

1. running too lean

2. insufficient cooling

3. excessive cylinder pressure << this can be a mechanical issue, or timing.

I know it's a lot of work, but can you swap a couple known good mags into the engine and test? Before you do, make sure you don't have a crossed or arcing plug wire. Also check for a dead wire or plug.

I find it unusual that only one cylinder is running hot. Could be mechanical (would hate for you to find a bad cam or a cam not degreed properly, but that would usually effect all cylinders). Could also be something like a temp sensor that's reading incorrectly. Try swapping sensors with another cylinder and see if the problem follows that sensor.

If neither a sensor or mag, I'd get a Lycoming rep involved. We pay big money for these engines, and trust our lives with them. They should be right.

Jim "Doc Griff" Griffin

PA28 - 161

Chicago area

Jim has great feedback. If this was an injected engine the first suspect would be the injector. At full power even an induction leak should not matter much as the MP pressure is so close to ambient. To be too hot you would need to be off timing, too lean or not cooling as Jim pointed out. Too lean is tough to do in a carbureted engine (for a single cylinder).

Does it run equally rough on both mags? New mags should not need that much timing adjustment in the first 500 hrs. I would have this overhauled at a good shop even if new and have the timing process video taped on next install.

You are not being picky at all. It should purr like a kitten with no compromises.

Do you have any engine data you can share. What is your full power fuel flow? All EGT's should be in the 1300 range on take off.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

One other test you can do (if you have not already) is lean out the engine and run at mag check power settings on a single mag and seeing if it is smoother on either one.

I have read again from the beginning and the one thing that really stands out is kickback and rough running. If the mags were mis-timed originally they could have both been damaged by a kickback event. To get kick back it really has to be incorrectly timed and although it could be valve timing it is more likely ignition timing - especially since it responded to changes in timing.

Here is a TCM Service Bulletin I found on this. http://www.tcmlink.com/pdf2/SB16-6.pdf

FYI: The TCM starter adapter was originally a medieval torture device adopted for engine use. It combines high orthogonal torque loads, a dodgy spring, and dubious compatibility with PM starters all in a compact, wildly expensive form factor in 15+ different configurations.

Also:

https://www.qaa.com/magneto-troubleshooting-guide

https://www.bonanza.org/community/member-forum/general-discussion/posts/mar-2018/start-on-the-left-mag/

https://www.aircraftmagnetoservice.net/magneto-troubleshooting-guide

https://www.casa.gov.au/file/79426/download?token=P1wnoPhv

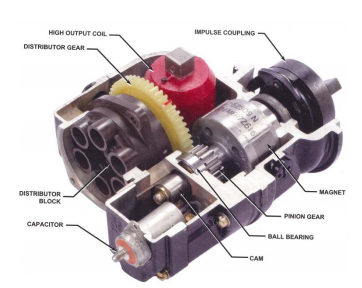

A picture from the last link which covers many failure modes

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Dtaglila;

Sorry to hear what you're going through. It's safe to say that if we had to go through what you're experiencing, every one of us would be just as frustrated. Wish there was more we could do. Please keep us updated.

Jim "Doc Griff" Griffin

PA28 - 161

Chicago area

I am sorry this has ended up so complicated with Lycoming. If you have to buy new replacement mags out of pocket that does not seem fair.

Can you confirm:

1) It will idle at the right idle rpm (even if rough)

2) When you lean it out the rpm will rise before the engine cuts out. At least 25 rpm.

3) I agree on the cold cylinder test

4) Does it run the same on either mag?

5) Is there a possibility the timing is off? Could the flywheel markings be in the wrong position? What process was used for timing?

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

did you time off of the flywheel markings or by the piston #1 TDC? Wild theory that the flywheel would be incorrectly marked.

another thing to try would be pulling carb heat at idle to see if it runs smoother

https://resources.savvyaviation.com/wp-content/uploads/articles_eaa/EAA_2013-11_rough-engine.pdf

More Lycoming guidance:

https://www.aviationconsumer.com/maintenance/carburetor-idle-issues-check-the-mixture-first/

I found another reference somewhere for unusual roughness. In this case it was a small air leak on the fuel feed to the carburetor that would bring bubbles to the system and lean out the mixture.

You could also consider a LOP mag test where you run at 65% lean of peak and switch mags. This test is very good at picking out and weakness in plugs and harness but might be indeterminate if there is a systemic timing issue. If the engine dies on one mag go to mixture cutoff as the raw fuel can explode in the exhaust if you go immediately back to the both mags.

This test is more conclusive at altitude but can also be done on the ground.

Another mag article

https://www.kitplanes.com/magneto-timing/

What is the exact engine model? and what is the dataplate compression and advance? There are some engines that are 23 or 20 and not 25.

More info on timing:

https://www.lycoming.com/sites/default/files/Engine Timing Marks.pdf

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Dtagilia;

Eric's post reminded me of one other obscure thing to check, the gascolator gasket. Usually they will leak fuel out, but they can also suck air in, and in severe cases, can cause engine stoppage.

Jim "Doc Griff" Griffin

PA28 - 161

Chicago area

Jim, good point. Another test would be with/without the electric boost pump. Also, are there fuel lines with different routing or lacking a heat shield? This could be a factor if it is worse hot.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Thanks for the suggestions, I will investigate all of them. Right now working on a list of possible cause and will start working them one by one. The suggestions you provided will be on the list. Still have a tough time with the way Lycoming handles warranty work? I would think their customer service would be top notch especially when you buy a zero time motor. At this point with 20/20 hindsight I would have paid more to have my original engine done just to have the great customer service I have gotten from Don George Engines in Orlando. Thanks everyone for your comments, I just want to get it fixed so I can continue to enjoy it.

1) In regards to your warranty issues, stop fooling around with Lycoming and call the CEO of Textron.

I had issues in the past with service and warranty issues.

Call to the CEO on two occasions resulted in quick, and

Satisfactory resolution to both problems

2) Pull the left mag, make sure the gears are properly

Indexed if they are off one tooth the timing will

be off.

3) For timing use time rite or the eastern gauge, the

Ring gear may not be properly indexed.

4) As far as checking the valve clearance the limits

In one of the above posts, those clearances are

for dry tappets and that would require disassembly

Of the valve train to remove the oil from the tappets.

Note: When you receive your mags before installing

Check the mag cam for proper lube before

Installing them. Insufficient lube will cause

Rapid wear which causes timing drift.

I hope the above diatribe is helpful the the one thing I am sure about is usually the CEO warranty is better

than the written warranty. Good luck on getting your

Issues resolved

Was any further adjustment to timing made? Encouraging that idle is now smooth. 110 drop is on the high side but if it is even between Mags I think ok. Does not explain the prior mag drift.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

What are take off fuel flows now at max power? How about EGT's?

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Thanks for the question, I don’t have a fuel flow meter, so answering that question would be a guess at best. The EGT are under 1400 during the climb out. The Dynamic balance corrected the prop unbalance from 0.49 IPS to 0.07 IPS. Engine smoother, but have times of being a little rough, then clears up and runs smooth. Still think, since I have a spare set of changing the harness just see if it makes any difference?

Might still be a little lean if 1400 on climb out. How hot it the air and fuel? Does the roughness clear up if you turn the pump on? That is a nice improvement in prop vibration.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)