Advice on the never-ending annual. Are we being unreasonable??

We put our plane into the shop “early” for an annual inspection at thanksgiving (was not due until February). This was the first annual for the plane we bought so there was an extensive list of stuff to do. We did not balk at the cost - we said do what we need to make the plane safe to fly and do it right.

We have replaced the stabilator - new pitot system - some engine repairs - reworked the panel to a 6 pack and now are waiting to get a crack in the door repaired

The door seems to be the big issue - our door is different than later model PA-28. We are told they have ordered 2 different doors that were supposed to fit and neither has come in. Our old door has been sent out to repair - which we did not care how it was fixed 6 months ago - just wanted the door fixed

So here we are at the middle of July - we still don’t have a door - but we can’t fly the thing anywhere to fix it - so what do we do other than just biting our tongue or screaming at the guy that has our plane half taken apart?

On the bright side - assuming the plane ever flies again - we have replaced the headliner - overhead console - seat covers and cushions - wall panels - and floor covering.

You don’t know the restraint I used in typing this without a dozen different profanities

Help??? Advice???

We have replaced the stabilator - new pitot system - some engine repairs - reworked the panel to a 6 pack and now are waiting to get a crack in the door repaired

The door seems to be the big issue - our door is different than later model PA-28. We are told they have ordered 2 different doors that were supposed to fit and neither has come in. Our old door has been sent out to repair - which we did not care how it was fixed 6 months ago - just wanted the door fixed

So here we are at the middle of July - we still don’t have a door - but we can’t fly the thing anywhere to fix it - so what do we do other than just biting our tongue or screaming at the guy that has our plane half taken apart?

On the bright side - assuming the plane ever flies again - we have replaced the headliner - overhead console - seat covers and cushions - wall panels - and floor covering.

You don’t know the restraint I used in typing this without a dozen different profanities

Help??? Advice???

Comments

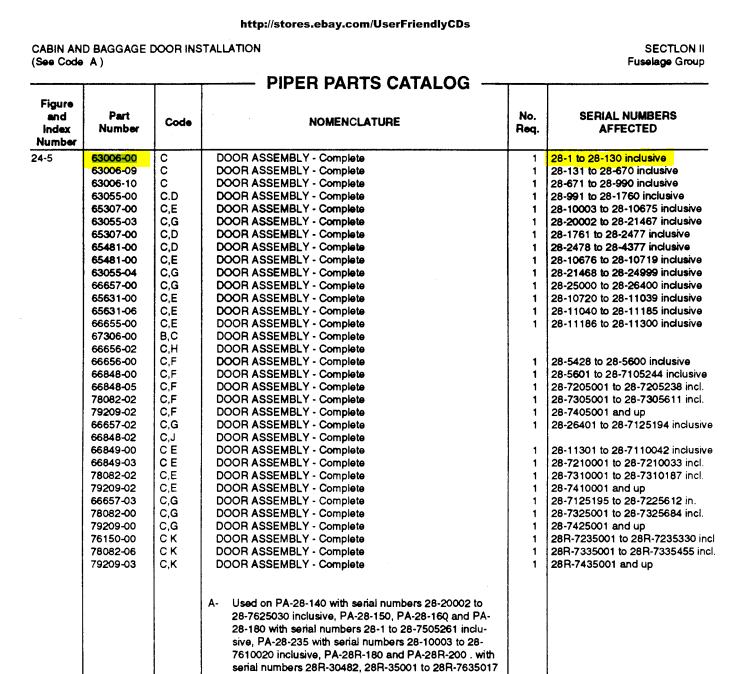

I think you need an early door as your serial number is P28-5 based on the registration. Here is the list from the parts catalog

Texas air salvage has one with issues but perhaps combined you can get a working one? Did they send yours out for metal work and if so to who? What exactly were they fixing? Where is the crack and how are the going to fix it?

https://www.texasairsalvage.com/main_view.php?editid1=194251

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

KD, you're doing great. Don't give up hope, this will come to an end. You're getting a super plane and your attention to detail will pay off with good looks, safety and pride. We're all with you on this and we can't wait to see the pics! Hang in there and I'll buy you a drink at Airventure!

Scott Sherer

Wright Brothers Master Pilot, FAA Commercial Pilot

I'm interested in your responses to Eric's questions and I'll add one; what is the reason the crack in the door could not be welded or repaired with a patch vs replacing the door?

Jim "Doc Griff" Griffin

PA28 - 161

Chicago area

The crack is at the lower hinge and extends down the lower radius of the door if that description makes any sense. There had been an earlier repair to the same area so it will make another repair more difficult I have no doubt. Getting another door for donor parts may help and will ask

Probably just needed to vent more than anything.

Thanks

I have had good luck with Texas air salvage in the past. It might be possible to pick up the door too vs shipping it which would be a big crate. If I was closer I would be happy to swing by and deliver.

My airplane partner on an RV10 and I once flew down to Tahoe from Portland to pick up a hardtop for an older Porsche. I drove down, he flew down and we swapped in Tahoe. The flight cost more than the hardtop but the experience was priceless

I would figure out who has your door and why they can't make any progress. Some shops will just stare at complicated projects - unable or too inexperienced to even begin. Other's with experience with the tasks would have it finished quickly.

Eric

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Will ask my mechanic about the tx air salvage part

Thanks for the help

Ok, hopefully a solution is found soon. Sounds like you have multiple paths. It does seem like most of the salvage doors are the later type.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Hi N5004W. I feel your "pain". My Aztec (purchased in early April) is still in the shop. I had hoped to fly it this year to OSH. Even if its ready this week, I wouldn't fly it to OSH as my spot landing skills in the twin have gotten too rusty. I need to feel confident I can put on the Orange dot. There have been many times I have wanted to scream because things are taking longer than expected. I'm doing a bunch of the work so I am partly to blame, if there is blame....

As others have said, and I totally agree with, the money and time you are investing now will pay dividends later. You will have a safer, more enjoyable bit of kit!! Take your time, get it right and you will be far happier.

I've used Texas Air for a few things for my Aztec. Solid shop, they " get er done". There are a few other places around that are Piper specialists. I'm sure Scott has a list. A&P shops are good, but sometimes you (as the owner) need to take the bull by the horns and do some leg work. I did that to solve a fuel leak issue. The shop didn't know who to call. I posted on the forms (mostly this one) and folks gave me recommendations. (Thanks Eric, Scott, and others) I then did the calling and ordering of stuff. Handed the shop parts and the relevant paperwork and problem fixed.

Don't give up hope. !!!!

Why were the stabilator and pitot lines replaced? Do you mean the hoses? Was the stab. beaten up, or badly corroded? It seems very strange to replace a whole stab.

The plastic pitot lines were cracked so he put in new plastic tubes

The pitot/static lines are originally aluminum, and rubber. I would also recommend looking at all of the ribs on the vert./horiz. stabs. and rudder for corrosion. I also had an elongated fwd. fitting on the horiz. stab. that mounts the counterweight. Also look at the interior step bracket for cracks. This is stuff that is probably never looked at on an annual. I’m in the middle of a restoration.

I think the average age of the “covid” victim is at least 70 with co-morbidities, or someone with a compromised immune system, so if he’s in pretty good health he should be ok, unless they commit medical malpractice for money, (the govt. incentivized covid diagnosis and respirator use) which has been going on wholesale. Sad. I should have also mentioned that all of your hydraulic and fuel hoses should be checked, as well (they’re supposed to be replaced every 8 yrs., but I doubt many people do. You can buy a whole set from a place in Tulsa, if you need them.

Please do as pilotnmech suggests. I got my plane out of annual, all went well, but fuel hoses weren't replaced. This led to a fuel leak, electrical problems and forced landing. ATC was awesome. I've posted the article on this site, 3 Issues at the same time Time to call emergency Don't experience this, check the hoses. And a major annual as yours is, hang in there, one of mine took several months when Panel was being redone, then carpet, upholstry, etc.

Hello to N5004W, it is indeed very unfortunate that your plane was in the shop all that long. What I find hard to understand is why a plane that flew in for annual would have a door so bad it required replacement. It is not necessarily easy to swap one door to another aircraft. The fit is often a bit different. Since owning my shop since 1976 we have never had to replace a door. We have repaired many with metal and rivets and even had several welded in by the lower hinge where they often crack. Getting the proper fit is often the hardest. Good luck with your plane. Pete Conner

Actually I think it is crazy. One question I have is how did you brief the shop at the start? And what did they do in response? Did you get a proper and detailed response(back-brief) This also depends on what sort of PPI was conducted. I am assuming that one was not conducted(because then the issues should have been known/anticipated).

Because it was the first annual in your hands I would have which ADs needed to be conducted, methodology to each one in case you could do a fix on one that made $ sense. All time expired parts replaced, compression test, avionics check, probably replace sparkplugs unless done recently, oil analysis, flush and replace. Inspection of all control cables, mixture and fuel cables, carb heat too. Full inspection of the fuel system. Mags, prob rebuild, carb checked, float examined. All lights(panel/external checked for night flying, assuming not IFR. I would then go for LEDs all around. Tires checked for age and condition. Over 8 years I would throw them regardless of tread left, the rubber is probably end of life. Brakes etc. Throw in ADS-B in/out and make sure the GPS is up to your mission and the database is UTD.

Go to inertia belts for front if not installed, check webbing and replace if required. Update first aid kit. Prob Change ELT battery and main bat. And the rest.

Do a external clean and polish(yourself so you can examine closely, know your aircraft and identify change.

I suppose you get the picture. I say all this because I assume you are going to fly the plane for a number of years.

This all needs to be planned and briefed both ways. Consider sourcing all parts yourself to 1. Save his time(and cost) 2. Free him up to do the real work(not be surfing the ole internet for parts while having a nice coffee instead of hanging in the chilly hanger).

I did this on a Piper Navajo I brought a little over two years ago and it hadn't flown for 6 years. I have had very little go wrong since, pretty normal stuff. But what the 5 month process did was make me confident in the aircraft and it has been available to fly. it I have done 200 hrs in it since Jan 20 including a five month lock down for Covid. It didn't cost that much and most of the stuff I talked about are really consumables when you think of it.

I would be asking hard question why that door wasn't prioritised early. Also it should be fixable IMO.

Or is what I am suggesting over the top?

I had heard the same issues with the fit when replacing rather than repairing doors so I am glad we ended up going that way.

I think we may be seeing the finish line - or at least getting close

Thanks for the suggestions