Dehydrator Plans

There was a brief article in the August 2021 PIPER MAGAZINE and would like more details on the plans to build and assemble and operations.

There was a brief article in the August 2021 PIPER MAGAZINE and would like more details on the plans to build and assemble and operations.

Comments

Already built engine dehydrator units are available from most of the major suppliers. Here's one from Aircraft Spruce: https://www.aircraftspruce.com/search/search.php?s=dehydrator

If you are a DIY person, then the internet is your friend. I typed "DIY airplane engine dehydrator" into my search engine and it listed dozens of articles and videos. Some articles were for other aircraft brands and experimentals, so you'll have to adapt their plans to your plane, but the concept is the same.

YouTube also has a number of videos on how to build your own engine dehydrator. Check them out and let us know what you decide!

Jim "Doc Griff" Griffin

PA28 - 161

Chicago area

I'll get some more help here -- sorry we didn't notice this thread earlier and get you more help.

Digital Product Manager

Piper Owner Society

@Gcox652021, this was my article, what details do you need? Glad to help.

Joshua, where can download the file for the 3D printed oil fill adapter? I’d like to print one out for my dessicator. Thanks!

Greg Arserio | PP-ASEL-Instrument | N8390C 1976 Archer II | Rochester, NY (Based at KSDC)

Here is the .stl file. I had to compress it for the site to allow me upload it.

Joshua, Thanks! Part looks awesome!

Greg Arserio | PP-ASEL-Instrument | N8390C 1976 Archer II | Rochester, NY (Based at KSDC)

Hi Joshua, I am putting together the parts for a dehydrator. Where did you get your silica beads?

Ken Hoke

1976 PA-32-300 Cherokee Six

KLOU

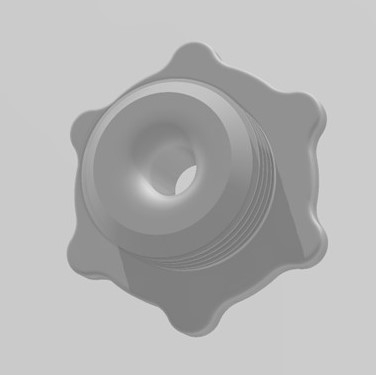

I just finished a homebrew dehydrator and created a 3D print for an oil dipstick to 1/4" barbed fitting - uses a 7/16" o-ring for the seal. If there's any interest, I can see about posting the STL.

Hi, I would be interested in that STL.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Here is the Adapter and the attached STL file (zip form).

Adapter with 1/4" barb fitting for Continental engine (TSIO-360) dipstick. Used for homemade dehydrator. Uses a 7/16" O-ring. Sliced using Prusa Slicer using 0.15mm layers with 3 perimeters, 30% concentric infill and no supports. Printed with PLA and it will melt if used on a hot engine. Some minor cleanup of O-Ring notch may be needed. Fit with a 7/16" OD O-Ring into the groove near the bottom, attach a 1/4" ID hose and it should fit snugly into the top of the dipstick tube. Comments and suggestions welcome.

DJ