1967 Piper Arrow Gear Hydraulic Pump Motor

So, I purchased my second Arrow (N3740T) a few years ago, and as expected I have been working thru the typical minor annoyances (soft brakes, bad seals, excess abandoned wiring, etc.) I have run into a situation that I would hope that others might provide insightful guidance re. my gear hydraulic pump. After flying the Arrow around for 2.5 yrs. the gear has retracted and extended reliably until recently. I notices last month that when I raise the gear the yellow "in transit" light comes on but does not turn off. I lowered the gear and got three greens and then tried to raise the gear again - same thing, the "in transit" light came on but never turned off. So well, I lowered the gear (three greens) and then returned to my home airport. I jacked up the plane and actuated the gear and the gear retracts about ~ 1/4 of the way up and then I hear a "clunk" around the gear motor area, whereby the pump motor stops and the "in transit" light stays on. So my logical conclusion is that the hydraulic pump motor needs to be overhauled. So I sent the pump out to Aerospace Turbine Rotables, Inc. (Wichita KS) and they overhauled my pump (looks brand new now ($1,600) and was tested with the appropriate paperwork). I installed the unit today and I still have the same problem ( gear only retracts ~ 1/4 up and then I hear a "clunk" and the gear motor stops. I replaced the two Cole-Hersee 484-373 gear motor relays ~ two years ago (the old ones were corroded externally, due to battery acid fumes). Anyway, I would value insightful guidance from Cherokee Arrow members that may have faced this issue. I noted in the Cherokee service manual that the Arrow hydraulic pump has a thermal circuit breaker ( pg. 6-10) but I'm confident that the pump overhauler tested and passed this unit.

Comments

Any leaks from the gear cylinders? Was the hydraulic system completely flushed prior to install of the overhauled gear? Can you configure the system to manually raise the gear on the lifts - any unexpected drag?

I had an issue with my Seneca III gear motor. The pump failed and would not hold up the gear (so it would leak down to three green). The first replacement motor + flush worked for about 10 takeoffs and had the same issue. It was replaced and the new one has worked for 40+. They said it sounded stronger after install. My issue was internal leakdown in the pump. The newly installed pump was an overhauled replacement but I don't recall from where.

Yours sounds more like the hydraulic pump overpressure limit is reached or the up pressure switch is out of adjustment and the motor shuts off. 1/4 would likely me close to max pressure with the angles of the cylinders in the gear system?

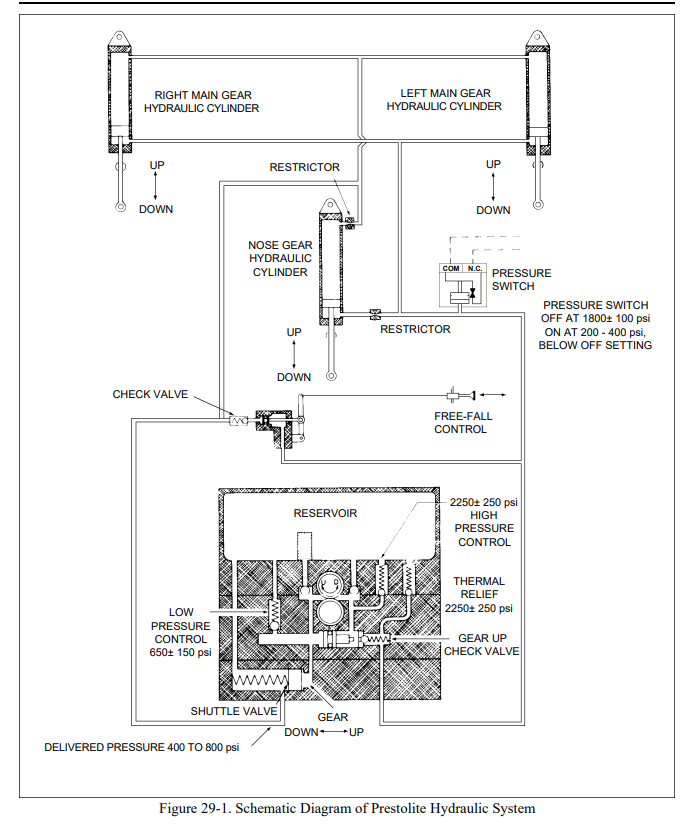

Here is a system diagram (Prestolite) from a Seneca

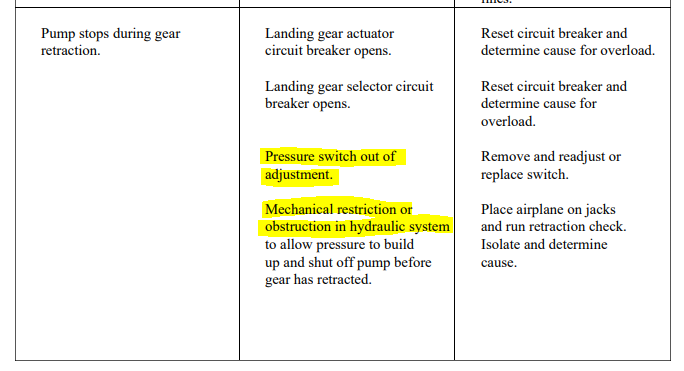

This is the maint manual troubleshooting for retraction. I would focus on the highlighted areas.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Thanks Eric. I will check the pressure switch setting.

Also check to make sure the vent is not obstructed on the gear motor fluid tank. The tank fluid level rises on retraction and if there is no space in the tank or it pressurizes because the vent is closed you could also trip the switch early.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

I had the exact thing happen to my '69 Arrow this past summer. I believe it ended up being a tiny hole in a baffle somewhere in the emergency gear override system. I ended up getting the override system removed instead of trying to fix it because it was about the same price. (And commercial training was getting annoying because I had to hold the override up the entire time during maneuvers.)

Unfortunately, another pilot totaled the aircraft with a gear-crumpling hard landing before I could fly it after that. But it worked for him! I will reach out to the mechanic to see exactly what it was and report back.

Ben S.

IFR Commercial Pilot

1999 Saratoga II TC (KCFO)

Denver, CO

This is a great discussion. For some comedy relief please refer to Table VIIA-1 on page 2J16 of Piper 753-586 (The 28R-180 service manual" What does the factory prescribe as the "official fix" for this problem? "Find cause and remedy." Firm grasp of the obvious!

What you've said all points to a problem with the control system, just like Ben and Eric are saying. You can verify this using a voltmeter while the plane is on jacks. Start with the voltmeter on the "UP" lug of the gear motor, and retract the gear. When the gear stops at the 1/4 point you'll probably see the reading on the meter drop from 12 volts to zero. Next, move the meter to the input lug on the overpressure sensor, and repeat the retraction experiment. If the input to the sensor still reads 12 volts when the gear stops moving at the 1/4 point, then the sensor "thinks" you're in an overpressure situation. You might then bench test the sensor, and check the lines for blockage or other restriction (kinks, etc).

Don't be surprised if the input to the sensor reads zero when the gear stops moving. I've seen at least two cases where the real culprit was the "weight on wheels," switch which is connected in series with the overpressure sensor. Usually these fail completely and permit no retraction. But sometimes with 50 years of corrosion and a bent "tang," they will engage as they move with the gear during retraction. If that's your root cause you're lucky because it's the cheapest to fix.

good luck,

Bob T.

Well, it gets better re. the landing gear in my 67 Arrow not fully retracting and the hydraulic pump stops mid-way with the "in-transit" light continuing to illuminate. First of all, thanks to all re. the constructive feedback. So, thus far, I have performed the following with no improvement.

OH hydraulic pump ($1,600) but the motor was last OH ~ 30 yrs. ago so I don't feel bad.

Flushed out the shuttle valve that is embedded in the adapter plate of the motor ( I couldn't remove the AL plug, even with heat, without destroying the plug and thus destroying the adapter plate. So I soaked the adapter plate in Brake-Kleen for ~ 4 hrs. and then blew out the cleaner and soaked it again overnight and then blew it out again). This was the best that I could do in cleaning the valve without destroying the adapter plate.

Working with my AP/IA, I raised the gear and the gear only went up ~ 1/4 of the way before the pump motor shut off again with the "in-transit" light remaining on. So we tried it again and this time he applied upward pressure on the left gear when it was going up. Now all three gear go up and the "in-transit" light turns off. We tried the same thing with the right gear and the right gear and nose gear go all the way up but the left gear was still down ~ 2 in from being full up. Then he went back to the left gear and applied additional upward pressure and then the hydraulic power pack turned back on and the "in-transit" light turned off and the power pack stopped.

So, we expected that the pressure switch was weak and was opening the electrical circuit to the pump prematurely.

So, I ordered a new pressure switch ($900.00) as it looked like this was the original switch from 1967 (so, I don't feel bad about replacing a ~ 50 yr. old pressure switch).

After installing this new switch today I attempted to raise the gear again and the same thing happened (main gear go up ~ 1/4 of the way and the pump motor stops with the "in-transit light" still on.

A helpful comment suggested that the squat switch may be opening when the gear is moving but this is not the case.

Any further insights would be helpful and I don't think there is any kind of binding in the actuators and there is no obstructions that we can see (the gear moves freely).

Stand by while I send this to our association A&P Erich Rempert.

Scott Sherer

Wright Brothers Master Pilot, FAA Commercial Pilot

Could you put a high pressure pressure gauge inline to monitor system pressures? Did you also flush out the entire system when you put in the new pump? What condition was the old fluid in?

You might remover the left hydraulic cylinder and see if it is contaminated, binding or clogged.

If you bypass the left cylinder does the system always work on the other wheels?

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Sorry to hear this has turned into a pain in the neck!

Is your newly-installed overpressure switch going open-circuit (measured with a voltmeter) when you reach the 1/4 retraction point?

I don't have a high pressure gauge and associated adapters to check pressure when the gear retracts. Thing is that the new pressure switch actuates when the gear raises ~ 1/4 of the way (just like the old one). I plan to flush the entire system tomorrow by removing each hydraulic line from each cylinder and then using my brake bleeding suction tool to suck as much fluid from each of the lines. As I do this I will also disconnect each cylinder and check for proper movement. None of the cylinders are leaking (if one or more had leaks I would see the hydro fluid and the pump would most likely keep running and, perhaps, not shut off).

I will check the voltage on the pressure switch when the pump stops to insure that the switch is actually open at that time. Thing is that my mechanic was able to actuator the pump by simply applying additional up pressure on the gear when the gear switch is up and the pump is not running before applying the additional force (which would reduce pressure in the system and thus close the switch).

Krelsey, your last comment makes me wonder if there is a clog in the left cylinder. If it is on the high pressure side it could seal tighter with increasing pressure and perhaps having 1/3 of the cylinders blocked at the highest "lift" force (at 1/4 retract) would trip the pressure limit.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Here's a reply from our association A&P Erich Rempert:

Sounds like you've methodically worked your way through the big ticket items, but it also sounds like it was time for those anyway.

I know you said the gear moves freely but double check for something like a brake line rubbing or hanging up on something like that especially on that LH gear.

Also have you considered internal leakage of the actuator(s)? On the Navion if any of the 4 actuators (one for each gear and flaps) have internal leakage your performance suffers greatly and one bad O-ring can cause the whole thing to just not "go".

The Piper is a little different system though, I suggest you start with the gear down and cycle it UP, when it stops shut the master off and see how the system behaves. If one or more gear come right back down that's sign of bypass somewhere. Also with the master off and the gear in its stopped spot see if you can identify anything by hand with the feel of the gear in that spot, it may be very stiff only in that spot or have some type of resistance that wasn't apparent before.

After skimming your message again it sounds like the new pressure switch has worsened your issue! Plumb in a hyd gauge and run some cycles and see what pressures you're actually getting. I suspect you'll find the pressures are correct...

Which will point the finger at obstructed flexible hydraulic hoses. I have seen this where old hydraulic fluid gets gummy and or attacks the rubber over many years and just like blocked arteries cause a massive restriction of fluid. This will cause the pressure to prematurely hit it's limits without the prescribed travel.

The remedy to that is have new flexible hoses built up. (You'll get a different answer from almost every one on hose life from 5 YEARS to "on condition"), if they are hard it's very possible they are also restricted. Since you've hit all the other items I'd look pretty closely at those at this point.

Good luck, update me on what you find!

~Erich Rempert, IA Consultant

Scott Sherer

Wright Brothers Master Pilot, FAA Commercial Pilot

Thanks for the insightful guidance Eric and all. So I purchased a pressure gauge set and removed the new pressure switch at the manifold and shorted the wires together (so the circuit is closed without the switch) and installed the pressure adapter and gauge in the hole where the switch was. I pulled the pump circuit breaker and then selected gear up and then pushed the pump pump breaker in and watched the gauge. The pump motor stopped at ~ 375 psi. with the main gear ~ 1/4 of the way up the gear switch is up and the pump breaker is still in and the pressure switch is removed and the circuit is continuous. I'm reviewing the electrical diagram again but believe the only thing that could cause this condition is an intermittent squat switch or associated wiring.

Good progress Krelsey! Could you bypass the squat switch? Does it always stop at 375? Since you have the pressure switch bypassed do you have a 2nd person ready to pull the breaker near full retraction?

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

krelsey, thank you for posting an update. It's very impressive how patiently and methodically you're working your way toward the root cause.

By the way, do you have the automatic gear extension system installed in your aircraft?

Bob T.

So, I met with my AP/IA today to further investigate this issue. I first asked him to inspect me hydraulic gauge attachment and setup to insure that my measurements would be correct. All is good, which I expected.

Also, BTW, the auto gear extension system has been removed, previously, and is not a factor here.

Anyway, I controlled the gear switch while pulling the circuit breaker in and out with each gear extension and retraction (the pressure switch was removed and the wiring was shorted). While I did this my mechanic was on his back at the left gear.

When I actuated the gear up switch the pump always stopped at ~ 350-400 psi. When my mechanic assisted by applying additional pressure on the left gear while it was retracting, all three gear retracted successfully and then the pressure spiked at ~ 2,000 - 2,200 psi before I could pull the circuit breaker to stop the pump.

So the hydraulic motor is good and the gear retract with the additional pressure. Also, there is no binding or interference anywhere that we can see.

I will check the state of the squat switch tomorrow.

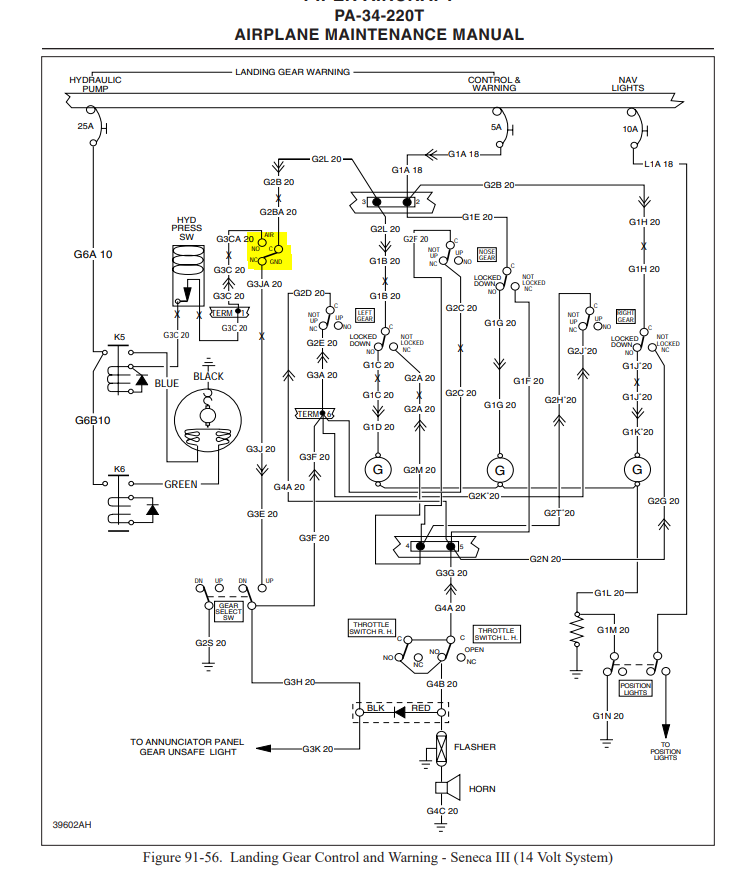

With two people you could also direct power the gear motor and isolate if it is some mechanical or fluid issue vs a electrical issue with a switch. It might be similar to the highlighted yellow area.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Okay, so here's the update today. Given the insightful guidance from 'empannin', among others. I bypassed all of the landing gear controls by simply shorting the gear-up contactor and controlled the gear actuation using the circuit breaker. So, all of the controls were removed (gear-up or down and the pressure sensor was removed and the wiring was shorted as always closed) while the pressure gauge was inserted into the manifold block. So, when I raised the gear using this method the fear raised ~ 80% of the way (nose gear came up fully but the main gear came up ~ 90%, and then the pump motor dragged and then stopped (and so I immediately pulled the circuit breaker). The pressure reading at the manifold was ~ 800 psi at this time)

So, the controls are no longer active in this test case (gear-up/down switch, squat switch and pressure sensor) and the hydraulic power pack has been overhauled. So my conclusion is this problem results with the shuttle valve located in the pump adapter plate. Would appreciate insightful guidance from all members re. my troubleshooting logic here.

BTW, there is no binding in all three landing gear systems that we can see as we pull each of the gear up/down manually without restriction.

Hi, are you saying that the main gear sticks out a little and doesn't fully retract? Can you post a picture? I can't recall ever owning a Piper with retractable gear where the main's retracted all of the way. On my Seminole's, 3 Seneca's and Arrow they stick out a little.

Scott Sherer

Wright Brothers Master Pilot, FAA Commercial Pilot

Well, before this happened the landing gear would fully retract and the gear doors were fully closed against the fuselage/wings as you would expect. I will take a picture when I resolve this issue.

Actually, no, I don't expect the main doors on Pipers to fully retract. I've never had one yet that fully retracted, sorry. That's why Lopresti, Knots2U and Laminar Flow System make main gear fairings. And if you Google "Arrow Landing Gear Swing" you'll find dozens of Arrow videos and not one fully retracts the main gear.

Scott Sherer

Wright Brothers Master Pilot, FAA Commercial Pilot

krelsey, could the main gear be manually pushed up all the way? did they leak down with power off?

I would not single out the shuttle valve yet as it seems bypassing the squat switch resolved the stop at 1/4 retract for the left gear. I would fix that and then re-enable the pressure switch, etc so you can do normal gear swings.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

Scott, yes you are correct that the gear stick down a little when fully retracted and the gear doors are closed. My Arrow has the Lopriest speed caps.

Thanks for the update. Wishing you a speedy fix

Scott Sherer

Wright Brothers Master Pilot, FAA Commercial Pilot

Just an update re. this issue. Today, I removed the hydraulic power pack again today and also removed the adapter plate in order to remove and clean the shuttle valve. I had to get mid evil in applying additional heat to the adapter plug. And I was successful in removing the plug (probably never removed for ~ 50 yrs.). I also removed the hydraulic connector to the high-pressure side and the two screws that are included in the assembly (I don't have a clew what these screws have anything to do with this issue but I cleaned all of this out with brake-kleen and also used a bunch of pipe cleaners to insure that all of the orifices are clear and clean. I reassembled the adapter plate to the power pack today and will reconnect the entire assembly tomorrow. I'm skeptical that this will fix this condition as I didn't see any kind of congealed hydraulic fluid in the shuttle valve. I have order a number of AN929 CAP FLARED ALUMINUM TUBE FITTINGs to cap-off each of the gear lines and actuators on at a time to help isolate this problem if the shuttle valve cleaning didn't resolve this condition.

It's going to be brand new when it is done. Thanks for keeping us updated. I think we discussed this previously but is the hydraulic gear oil at the right level? Were you able to flush out all the lines before motor install?

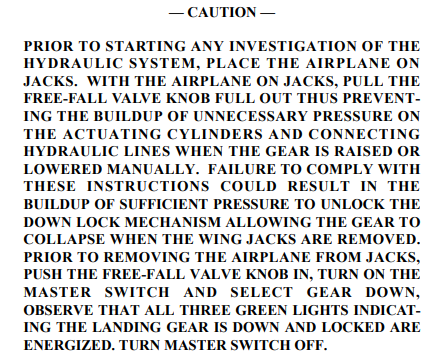

I would also recommend isolating the free fall valve and check valve as this would be an internal leak. You should also test it too. I also recall there are specific instructions on how the system should be set up before lowering it from the jacks to avoid collapse after maint.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)

So, here's the update today re. my hydraulic gear retract issue. After re-installing the power pack today (after cleaning out the adapter shuttle valve), I attempted a number of gear retracts with the high-side contactor shorted (the pullable circuit breaker was the only source to power the pump.) And guess what? The gear fully retracted and then I pulled the circuit breaker after all gear were fully retracted (approx 1600 psi before I pulled the circuit breaker) given my hydraulic gauge readings. I did this again a few times with the same results. So, the gear now retracts and extends as expected.

I reattached the new pressure sensor and un-shorted the gear-up relay contactor.

I then performed ~ 3 gear retracts using the designed system and was able to operate the gear as expected. Also, the emergency gear-down worked as expected multiple times.

So, I suspect that this problem was the result of a clogged shuttle valve, although I didn't observe any congealed hydraulic fluid clogging that would have caused this issue after removing and inspecting the spring and valve).

So, I believe that I have corrected this issue as the gear seems to work as expected.

My next steps are to replace all of the flexible hydraulic lines in this system and also squirrel-away main and nose gear hydraulic actuators (that are rebuildable) as available.

Great!

I am sure you know this but just in case.

Eric Panning

1981 Seneca III

Hillsboro, OR (KHIO)