It’s Never too Early to Prepare for Spring

By Jim Cavanagh

Many of us succumb to the ice, snow, and cold temperatures of winter, letting the airplane sit for a few months. It’s nothing to feel badly about; laying off for a while is something that happens to the best of us. When you are a pilot, however, you have a lot of responsibility to ensure that both the equipment and the person flying are actually ready to do the deed. An airplane demands a level of effort that is far beyond getting a boat or lawnmower ready for the season. There is a safety quotient that demands focused attention. With this guide, you will be sure to have your aircraft ready for spring.

Although the very best way to get an airplane ready to fly is to do an annual, it is a little overkill. There are things on an airplane that need to be addressed and others that time and cold simply don’t affect. The trim will be fine, brakes won’t wear and things won‘t break if you don’t use them. What affects an airplane are things that seep, leak or run, and things that corrode, harden or dry out. This means aircraft owners need to check the engine, hydraulics, fuel and rubber.

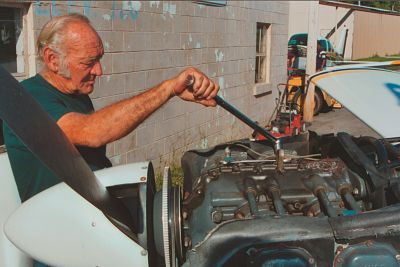

1 Remove the Cowling and Wheel Pants

First, you should pull the cowling and wheel pants if you have them for access to critical areas. This is something that keeps a lot of owners from doing proper maintenance because they sometimes need another person to assist them, which can be a hassle. However, it is one of the simplest hassles you have with an airplane and it can tell you a lot about your bird. Find a friend and give yourself access.

2 Check the Battery

Hopefully, before the airplane began its long winter’s nap, you pulled the battery and placed it in a warm closet or basement. Batteries suffer more than anything else in cold weather. If the charge gets too low, the water within the electrolyte solution will freeze, causing the plates within to come into contact and short out. This means a dead cell and a ruined battery.

3 Sump the Fuel System

While the battery is charging, go through the fuel system by sumping all of the drains and sumping them thoroughly. Check your fuel caps, especially the gaskets. They can harden and become embrittled, checking or shedding material right into the fuel. If you have a gascolator or an electric fuel pump, drain them completely and check the filter on the fuel pump. Re-safety the electric pump or have your mechanic do it.

Aviation fuel doesn’t age like auto fuel does, so there are no varnish problems, but if you burn auto fuel, it would be a good idea to get as much avgas into the system as you can. I always top off the tanks at the beginning of winter with avgas just for this reason. Remember that you will probably have to do some serious priming if you have a carbureted engine and the valve has been turned off in the cabin.

4 Check the Oil

When you check the oil, also check the logbook to see how much time is on the oil. Some guys will automatically change the oil at the beginning of the season. Oil takes about a year to breakdown and lose its good qualities and in cold weather, it takes even longer. The hardest thing on an engine’s innards during winter is the hot/cold cycles that create condensation and molecular movement within the oil.

It is too late for this past winter but next year, it would be a good idea to treat the oil with CamGuard or a similar product, something that is an additive package for oil that contains lubricating, corrosion-resistance chemicals. It is the best money you can spend on an aircraft engine.

The rest of this article can be seen only by paid members who are logged in.Have a website login already? Log in and start reading now.

Never created a website login before? Find your Customer Number (it’s on your mailing label) and register here.

JOIN HERE

Still have questions? Contact us here.