It was 1903 when Wilbur and Orville made the first powered flight in an aircraft. Orville got the honors, and his “panel” consisted of a tachometer for engine rpm, an anemometer to read wind speed (or airspeed), and a stopwatch so he could measure the length of the flight. That was the first aircraft panel.

It would be another 50 years before general aviation really took off. WWII brought a lot of attention to aviation, and the Servicemen’s Readjustment Act of 1944, otherwise known as the GI Bill, provided financial support to veterans who were inclined to learn how to fly.

Aircraft manufacturers like Piper and Cessna saw this and created aircraft for the market. When Piper added a nose wheel to the Pacer, creating the TriPacer, and Cessna introduced the 150, learning to fly became significantly easier, and GA grew.

Aircraft communications and navigation equipment were basic back then, and aircraft panels were simple. There was little in the way of equipment to install in an early GA panel, but the ’60s and ’70s saw an explosion of aircraft electronics manufacturers enter the market. King, Narco, Collins, Genave, and others introduced products designed to make flying safer, and aircraft manufacturers needed to find a place in their panels for all these new avionics.

Early attempts left a lot to be desired. The concept of the “center stack” had to wait while manufacturers found less-than-desirable locations for communications and navigation equipment. The concept of the standard “six-pack” had not hit home yet, and AIs, DGs, etc., were found in odd configurations, often in conflict with IFR flying.

Aircraft Panels WWI thru WWII

The dogfights in WWI were flown in VFR conditions, and aircraft like the British SE-5A (1917, photo top right) were equipped accordingly. The compass served as your primary direction device, with only basic engine instruments (and a machine gun or two).

Even back then, aircraft manufacturers put a little artistry into their panels! Somewhere between WWI and WWII, Elmer Sperry came along and invented the first gyro instrument, known today as the turn and bank indicator. Sperry had actually invented a gyro-driven autopilot as early as 1910. Many WWII pilots depended on the T&B to keep their aircraft upright.

The Boeing PT-13D Stearman played a significant role in pilot training in the early days of the war. The turn and bank provided the pilot with a primitive way to “keep ’em level” back then.

Post War Panels

Most of us consider the Piper Cub as the first real GA aircraft for the masses. The Cub is still considered a prize to own. I have a friend who owns two. He also has two Boeing Stearmans.

The original Cub stepped back a bit and gave you oil temp and pressure, rpm, altitude and airspeed (up to 140 mph!), and a compass. The turn and bank was gone, but the ball remained so you could keep the nose ahead while fighting all that adverse yaw from those big “dirty” wings.

The rest of this article can be seen only by paid members who are logged in.Have a website login already? Log in and start reading now.

Never created a website login before? Find your Customer Number (it’s on your mailing label) and register here.

Still have questions? Contact us here.

Conclusion

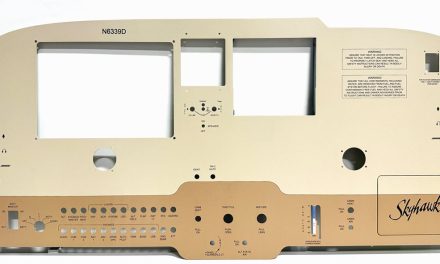

If you have a pre- to late-’60s aircraft with an original panel and are considering a significant avionics upgrade, and you plan to keep the aircraft for a while, consider including a new panel design in your project. If you’re adding Big Glass or a primary engine management system like the JPI EDM-930 or the Electronics International MVP-50, you are absolutely a candidate for a new panel.

Keep this in mind when getting avionics quotes. You are no longer focused on just getting a solid, reliable avionics installation, you’re looking for an artist: A shop that can turn an old factory panel into a work of art and, frankly, some of the new aftermarket panels are just that — works of art!

Until next time … Safe and Happy Flying!