A recent client asked me about the circuit breakers in his 1970 Grumman American AA-1 “Yankee.” They were original and he did not have the ability to pull them manually like we usually see on newer models. He asked my opinion, and I sent him an article that I wrote for the June 2013 issue of Cessna Owners magazine called “Annual Time.”

Mike had owned a Cessna Cardinal for seven years and flew it all around the country, including camping at Oshkosh. After selling the Cardinal he considered a Cirrus, got checked out, and put 35 hours on a rented SR22 before going into flying “hiatus” for a number of years. Upon returning to flying in 2022, he got the bug for a Vans RV-6, 7 or 9, and also considered a Cessna 140 or 170, but struggled to find an aircraft that would meet his standards. Meanwhile, he was driving an hour to rent “a doggy Tomahawk.” Frustrated by the 12-month process to buy, he came across the Grumman Yankee nearby and, after a thorough inspection by FletchAir, the Grumman specialists, he purchased the AA-1 to “just have something to fly!” Much to his surprise, he fell for the size and feel of the Grumman. I wasn’t surprised. I owned a 1973 Grumman AA-1B with 160 HP conversion that I bought for $20,000 (with 900 hrs. total time) in 1971. These aircraft are a ball to fly but they are slippery. Sneeze and you’re 15 degrees off heading and you’ve lost 100 feet! (I exaggerate.)

Annual

Mike was considering reequipping the AA-1 for Light IFR and using the Grumman the way he used to fly his Cardinal, so he asked my opinion. First, the numbers did not make sense. He would have $100,000 (with engine overhaul) in the AA-1, a big investment considering there is no autopilot currently available for the AA-1. I can’t imagine flying the Grumman in any IFR without an autopilot or even in extended VFR. Trio has an STC for the Grumman AA-5, for their Pro Pilot autopilot, and expects to have an STC for the AA-1 series in the near future. Until then, I don’t see the AA-1 (A or B) being a good cross-country aircraft, VFR or IFR.

Annual Time

Here are five avionics-related maintenance, repairs, or upgrades that you or your shop can address during an annual when the aircraft is open. Ideally, if your shop will allow, you can handle these yourself and save time and money. If your shop insists on doing these inspections and repairs, it may help you avoid avionics issues in the future when an avionics issue keeps you on the ground and frankly, is often more costly to address.

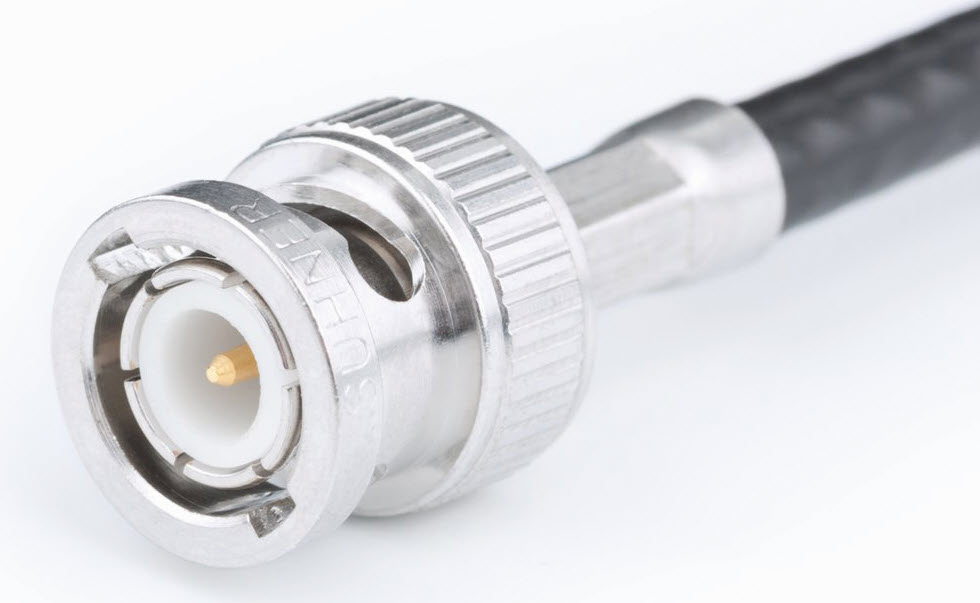

Antennas

While antennas are affordable, they can make or break an otherwise good radio installation. Visually inspect antennas and the seals around their bases for deterioration. Cracked antennas or poor seals allow moisture in while ultimately letting performance out. Replacement at annual will save you money. Purchase and provide the replacement antenna (if your mechanic will allow) for further savings. Don’t forget about belly antennas and the effect that a coating of engine oil can have on them. Transponder antennas are often placed on the belly right in the engine exhaust stream. If you’re wondering where that engine oil went, check your transponder and all belly-mounted antennas and remove the oil. Depending on how often you fly, this should probably be more of a preflight item than an annual event.

Have a website login already? Log in and start reading now.

Never created a website login before? Find your Customer Number (it’s on your mailing label) and register here.

JOIN HERE

Still have questions? Contact us here.