It’s not often we tell Piper Owner Society members about what’s happening in the Cessna or Beechcraft worlds, but a recent Service Bulletin related to oil and Continental-powered engines created such an interesting discussion that we decided to share it here.

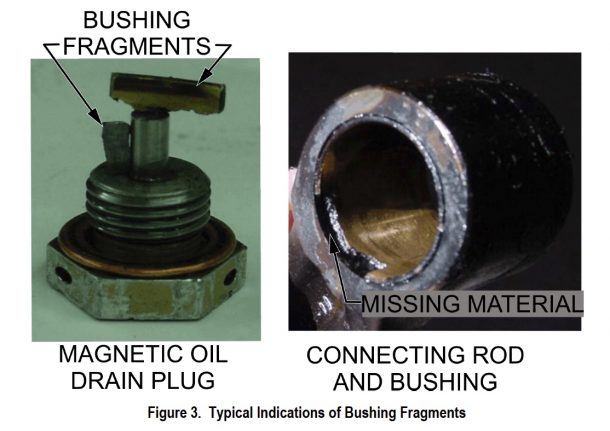

As background, Cessna parent company Textron Aviation issued two service letters covering most of its single and twin fleet. The letters come following Continental’s revision to its critical service bulletin CSB07-1A, which in turn was prompted by reports of piston pin bushing material being found in the oil sump and/or filter.

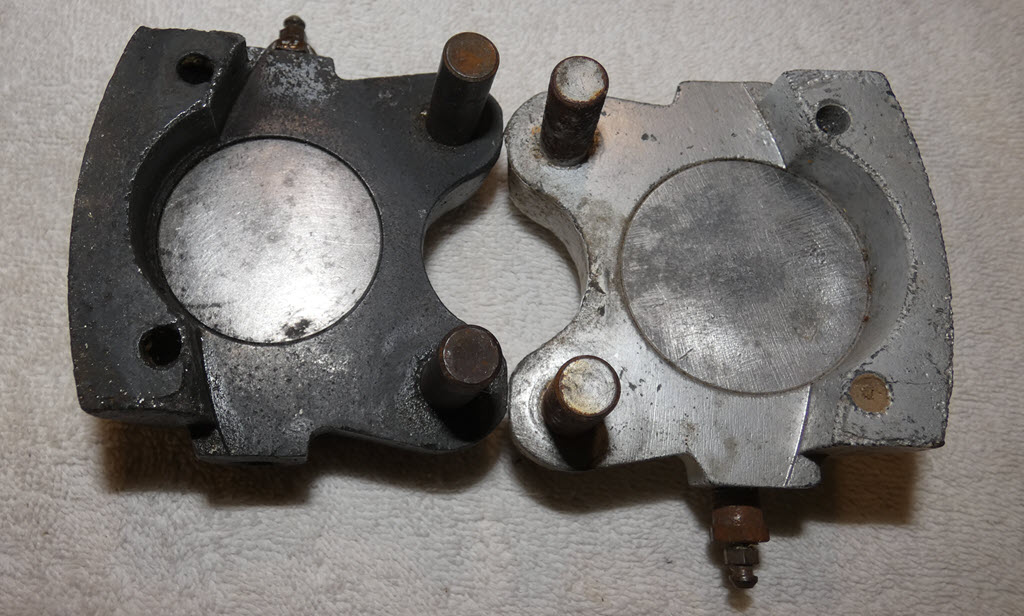

Compliance requires inspection of the connecting rod piston pin bushing as well as straining the oil and inspecting the oil filter during regular oil changes. During inspection, the A&P should look for signs of cracks emanating from the bushing split line, missing bushing material, and signs of bushing movement.

It led to the following discussion.

Member Question:

What are your thoughts on Critical Service Bulletin CSB07-1A? My takeaway is that it’s essentially a very thorough oil and filter change, with a detailed inspection of both the used oil and cutting open the filter. But as a mandatory Service Bulletin, it now sounds like cutting the filter and some sort of oil inspection is required at every change. The mechanic only gets called in if you find something, correct?

My other question relates to the actual piston pin bushing installed. Does it matter where these bushings were sourced, or is the problem related to the support any bushing receives from the piston and rod? Our club has two singles — a 182H and 150G — both with recent top-end overhauls and new Superior cylinders all around. We’ve been getting about 30-40 hours a month on each plane since a great recruitment drive last fall. We’ve been inspecting the filters and sending an oil sample out for analysis — so far, all good. I know the 182 has two drain plugs, so with the quick drain on one side I was contemplating getting a magnetic plug for the other. I’m not certain on the 150 as I’ve never had the lower cowl off, but it has a quick drain on it now.

Answer from A&P/IA Consultant Erich Rempert:

It’s not an AD, it’s a Service Bulletin. Mandatory, Critical, Super Critical, etc., all have the same legal weight. When operating under Part 91, Service Bulletins are not compulsory unless they are called out in an Airworthiness Directive, so you technically don’t have to do it at all.

That said, you should cut your oil filter and send a SOAP sample out for analysis at every oil change anyway! Oil analysis is about trend monitoring, not spot-checking. You need to have samples analyzed at every change in order to establish a baseline and subsequently notice changes over time.

I think straining the drain oil is probably a good idea, too, and I think I’m going to look into getting one of the screens they call out in this Service Bulletin as it seems like an easy step that could catch something (literally) you might otherwise miss.

If you ever find anything questionable in your filter, SOAP report, or drain oil, you should get your mechanic involved for another set of eyes on it. If it’s determined you have wrist pin bushing material in your oil, you’ll have to pull all the jugs off again for an IRAN.

This is a good Service Bulletin to keep handy as a reference to look over at every oil change, regardless of the engine and what it’s on.

[Ed. Note: To read and download the Service Bulletin, Click Here]