What happens when the Piper Owner Society puts its mind to a maintenance problem? An extremely detailed look at Piper struts. This discussion is from the Piper Owner Society forum at piperowner.org/talk. Please note that a member supplied 3D printing files so you can create your own strut-checking tool.

Q

Anyone have any experience changing out your own strut hydraulic fluid? Is it worth buying the Bogert service tools? Is it worth buying or renting your own nitrogen tanks vs. using a good air compressor to refill the gas? Thank you for any advice, tricks, etc.

— zanede

A

A small N2 tank with a regulator is a modest investment and handy to have for filling tires, etc., when you don’t want to drag a compressor around. Bogert makes a kit to service struts. You can get a 10x kicker pump to go from 150 psi to 1,500 psi for around $300.

You might also find other pilots at your field interested in going in with you on the hardware. At our field (KHIO), there is a group of pilots that swap gear like borescopes, O2 filling tanks, jacks, scales, etc. It is possible someone already has this hardware on the field.

This is very common in the experimental community (where the range of things that can be done is very broad) to include prop balancing hardware, etc.

— Eric Panning

A

These are great tips! I hate having to pay large sums every time I have to get a puff or two of nitrogen. The Schrader valve was leaking; I got it replaced by my A&P, and nitrogen added. No fluid change. Cost around $100. Looks like it wouldn’t take many times to pay for my own tools…

Was planning to get the Bogert fluid changing kit for $220 or so, was hoping a nitrogen tank would have pressure in the cylinder by itself.

Can get a $90 small tank, exchange it for a full one for around $30, and $30 for a gallon of hydraulic fluid. Add the Bogert fluid changing tool, and maybe the kicker pump, looking at around $700 for a setup. Should pay for itself in a couple of years?

— zanede

[Ed. Note: Jim “Griff” Griffin here chimed in with this advice if somebody wants to fully rebuild their struts, which can be done periodically.]

A

- It’s not an extremely difficult job, but it’s very messy. My tips for rebuilding the struts, if you want to go that route:

- Make sure you have someone with you who has done this job before to help and guide you.

- Do not wear even halfway decent work clothes. They will get trashed.

- A large flat pan under the strut to catch the hydraulic fluid is a must.

- So are a good jack and aircraft jack stands.

- The retaining clips are probably the most frustrating part of the job, but take your time and work through it.

- Be careful reassembling the struts. There are sharp edges that can cut the new seals. Take your time.

- Work slowly. If something doesn’t fit right, don’t force it together. Disassemble, determine why, fix, and reassemble.

- Before you take everything apart, and while it’s still under pressure, I would recommend checking the Schrader valve at the top of the strut. A little soapy water will expose any leaks. If it’s leaking, address it while you have the strut apart.

- The struts take somewhere around 200-250 psi if memory serves me. If you use air, you’ll need a “kicker” compressor to get that kind of pressure. A standard compressor will only get you to about 120 psi.

— Jim “Griff” Griffin

A

- I don’t think they will need a rebuild. My reasons for a fluid change are:

- The fluid from the right main gear was dark, black, smelled old (that “old oil” smell.)

- It no longer seems to be leaking — it has a new Schrader valve, no oil on the strut, etc., it’s dry up around the valve. It never goes all the way down but has dropped some with the weather change (probably not related).

- The logbooks do not reveal any past fluid changes.

- My hopes are to put in fresh fluid and recharge with nitrogen, then I may restore a good steady height and hopefully prevent any seal or wiper problems in the future, maybe saving an actual rebuild. Otherwise, I would like the convenience of being able to add nitrogen occasionally as needed when things are a bit off, without being too obsessive with it.

- Does anyone know if a small nitrogen tank by itself has enough pressure to recharge or add additional charge to the struts without jacking up the plane?

— zanede

A

A small tank is still at a couple thousand PSI, but most would have a HP to LP regulator attached. I think for the time it takes to jack the plane it would be much safer to jack it and apply ~200 psi. Jacking the plane up is also a good time to check out the plane gear for anything unusual, too.

— Eric Panning

A

When I bought my Archer, the struts had about an inch of extension … kind of a low rider! I had a local A&P add nitrogen to bring things up to normal, and about a month later, it started to sag. Figuring it would probably need all struts rebuilt/resealed, I decided to give this stuff a try: “Granville’s strut seal.”

I also bought the Bogert strut servicing kit that has two one-gallon jugs and followed the instructions for changing out the fluid. It was a piece of cake and not messy at all. When my struts had nice clean pink hydraulic fluid all around, I added the strut additive, jacked the plane up for full strut extension, and added 170 pounds of nitrogen to the mains and, if I recall correctly, 125 pounds to the nose.

About three months later, it needed a small touch of nitrogen in the left main strut. It was then good for about six months, or when it started getting really cold, so I added a small touch of nitrogen to both mains. Now four years later, I still have to touch up the mains about every six months. The nose only needs checking about once a year.

I did buy a nitrogen bottle and regulator, about $300, and I have been using it to fill my tires as needed and maintain the struts. It started with right about 2,000 pounds and still has over 1,000 pounds left from the original charge.

On the nitrogen bottle, I plumbed it, so the tire refilling and strut refilling are separate to reduce the chance of getting hydraulic fluid into the tires. They both use the same pressure regulator, just with it adjusted to 100 psi for the tires and 170 or 125 as needed for the struts. It did require a little over 3.5 quarts to completely flush all three struts.

The Bogert strut service equipment: “Bogert Aviation Deluxe Strut Service Tool,” at AircraftSpruce.com.

— Ray McNaught

A

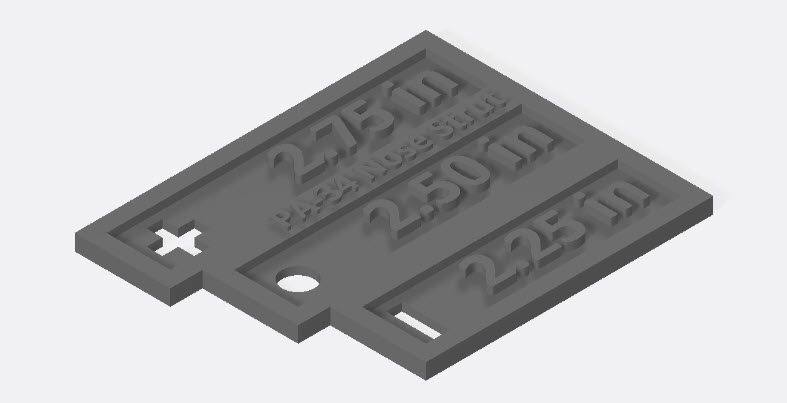

I will add that you can cut a block of wood to match strut maximum and minimum heights and use as a quick go/no-go gauge. When I had a Cirrus, we used something similar to slide under the wheel pants. When it started to rub, you knew the air in the tires was low.

— Eric Panning

A

The seal restoration fluid has been mentioned a lot on other forums and several A&Ps swear that it is really great at preventing a complete strut overhaul. Apparently, it reconditions the current seals and causes them to swell back to original dimensions.

— zanede

A

I decided to try this fluid purported to recondition the strut seals and restore proper strut action. I took the kit to a well-respected shop and took a day off from work to watch the procedure. It took a good while, as to get the requisite strut extension to properly fill the strut, the scissors had to be disconnected.

Finally the struts were filled, job done, and they gently set the airplane back on the ground and removed the jacks while I watched … at which point all three struts exploded, spewing the expensive “magic fluid” in puddles of red goo under each wheel! If I had not witnessed the entire scenario in person, and had the shop called me to explain why now all three needed a complete overhaul, I would NEVER have believed them.

Even after a complete seal rebuild, trying to maintain the book extension values is difficult as their extension depends on so many factors including strut wear, aircraft weight, greaser landings that inevitably leave one strut temporarily higher than the other, ambient temperature, dirt on the strut, etc.

A suggestion is to check the book extension figure. After a proper service to the book extension values, give yourself a reasonable margin of error (perhaps 20%) in strut extension. If they are approaching flat, you see a definite trend over time, or a visible fluid leak, then it’s time for service. Oh, and resist the urge to just “tap” the valve to let a “little” air out to lower a strut. At those pressures, they can go flat in an instant.

If you feel you MUST do some regular maintenance on the strut, may I suggest just keeping them clean.

— Mike Jones

A

I have one strut that rides low consistently. I had some nitrogen added once, and it was found it needed a new valve core. It held the proper height for a few months. Since then, it has been low intermittently. Occasionally after landing you can feel a drop on that side while taxiing. I read somewhere that can mean it is low on fluid.

So I plan to replace this fluid, recharge with nitrogen, and see how she does. I plan to have the A&P involved as well, even though it is considered maintenance. Don’t want things exploding everywhere for sure!

— zanede

[Ed. Note: Visit the forum for a link to the 3D print files referenced below.]

A

I designed and 3D printed Go/No-Go gauges for my PA-28-181. Feel free to download the 3D print files.

— garserio