Make Your Cabin New Again

By John A. Bradley

A major problem with older aircraft is the condition of the interior plastic trim. The trim is generally in very poor condition, with various cracks in the trim and deformation around the screw holes.

Aircraft trim material is generally polyvinyl chloride (PVC), the same material as modern plastic pipe. The trim material is soluble with methyl ethyl ketone (MEK), as is plastic pipe, which allows repairs to be made with fiberglass cloth and polyester resin. The polyester resin is also soluble with MEK, allowing the resin to chemically bond to the PVC material.

Get Started

The first step is to evaluate the condition of the trim piece. Some pieces will require a significant amount of labor to repair. The cost of a new piece should be considered before executing the repair of the old part. Much of this old trim is very brittle and beyond the point of no return. However, with time and patience, badly deteriorated or cracked parts can be restored to serviceable condition.

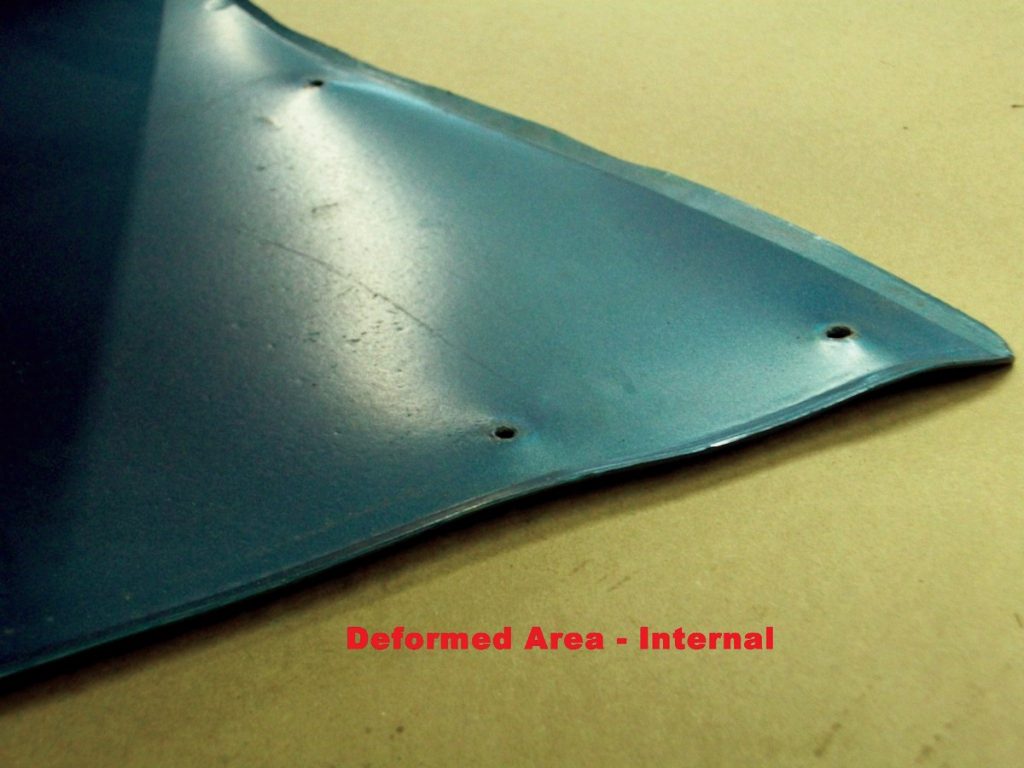

Aircraft trim parts are generally around .030-inch thick and flimsy, making it somewhat difficult to work with. Most older parts are usually deformed by heat and screws holding the parts in place. Straightening the parts requires a bit of labor but you can be successful if you take your time. Typical deformation caused by screws is shown at right. Waviness between the screw holes is almost always found.

Straightening

STRAIGHTENING SUPPLIES AND TOOLS

- A small heat gun. Grainger’s 4HWK1 is good. A large gun is too hot (1,000-1,500 degrees F) and will end up melting or burning the part.

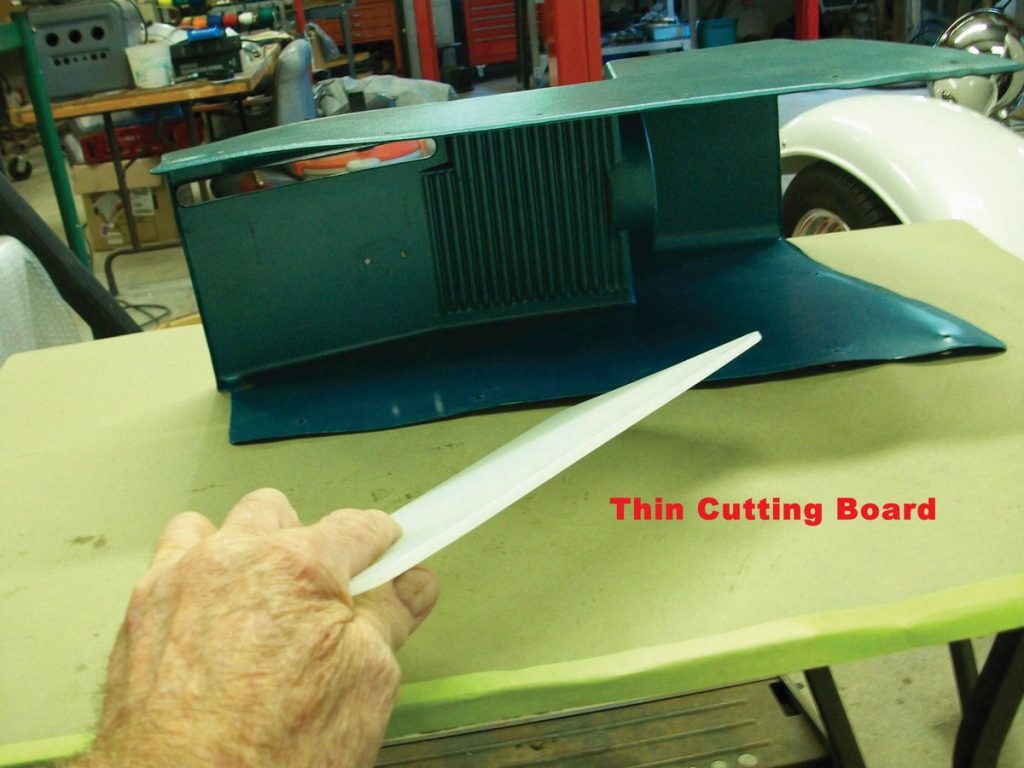

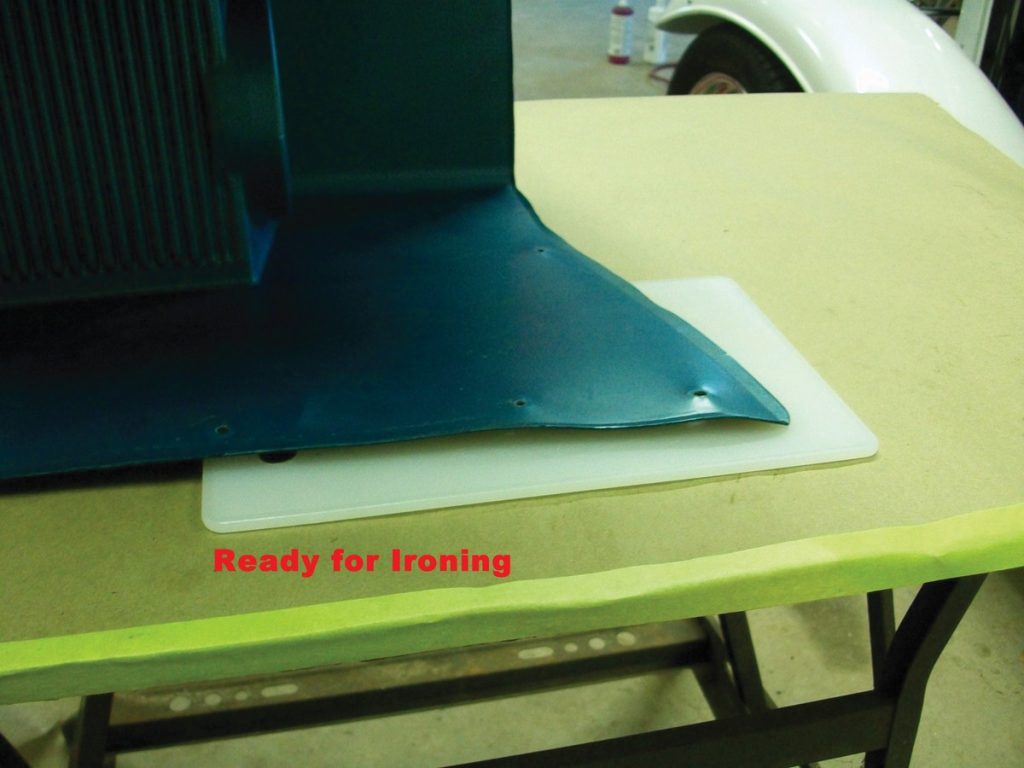

- A small, thin nylon cutting board. The cheapest Walmart one will do (or sneak one out of your kitchen).

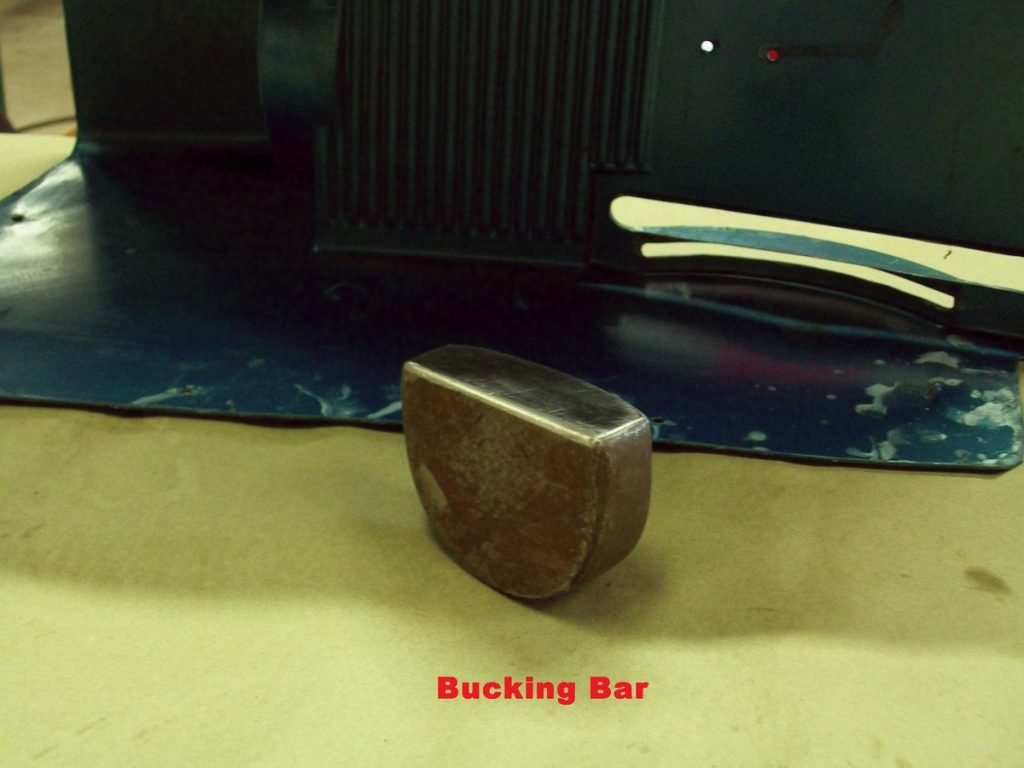

- A smooth steel block or bucking bar.

- A good leather glove to keep from frying your hands.

- Some good country music to soothe and keep focused on the job.

Click images to enlarge

To straighten, heat the plastic in an area of about 2 inches in diameter around the screw hole to the point where it can be reshaped. Keep the heat gun about 3 inches from the part while heating. Watch the material while heating and stop heating if there is any discoloration of the plastic. It will melt or burn shortly after discoloration. Remember, “Only you can prevent trim fires.”

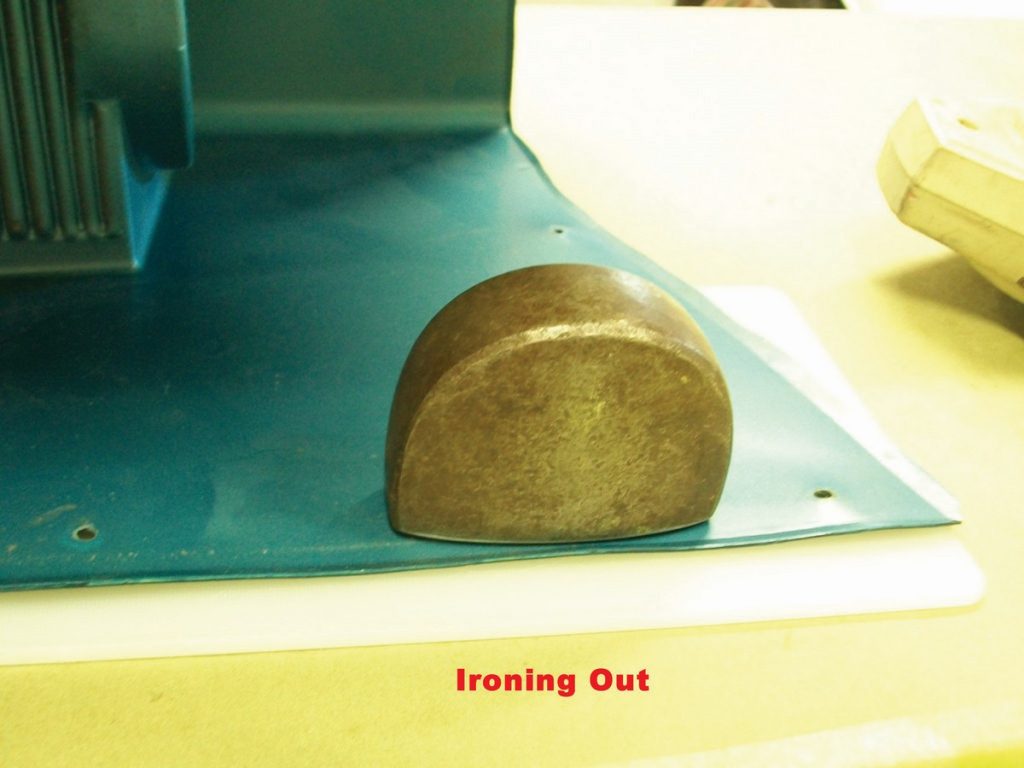

Keep the part over the cutting board while heating. Check the part for softness with a gloved hand. Apply the steel bar to the part to flatten out the deformation. Pretend you are ironing your good silk shirt.

Several reheats may be required to get a good flat surface. A larger area may have to be reheated to get good results. Many times, I will heat a part and use my gloved hand to bend a part, so it looks straight. The process will take a while to get the feel of the straightening. However, reheating can be done an unlimited number of times if the part is not scorched or burned.

Cleaning and Repairing

CLEANING AND REPAIRING SUPPLIES AND TOOLS

- One gallon MEK (Methyl Ethyl Ketone). Not cheap but necessary.

- Chemical-resistant gloves. MEK is quickly absorbed in the skin, so gloves are a must. Surgical gloves will melt when touched by MEK. Rubber gloves from Walmart, Lowe’s, or Home Depot will not work. I use industrial-strength, long nitrile gloves from Grainger.

- 80-grit sandpaper. 3M 2-inch-wide roll paper works great.

- Lint-free rags. Old T-shirts are great.

- A good respirator. Breathing MEK fumes will cause severe health problems. 3M’s 6000 mask and chemical vapor filter are available at Grainger.

- Several 1-pound coffee cans or small plastic paint mixing cups. All automotive paint suppliers have them.

- Reichold Polylite 33338-15 fiberglass resin. The stuff from your local auto parts store, Lowe’s or The Home Depot is low quality and not recommended.

- Hardener. Syrgis Norox MEKP-9.

- 520 plain-weave fiberglass boat and tooling tape, 8 oz/sq yd. Comes in 3-12-inch-wide rolls.

- Resin, hardener, and tape obtained from a boat repair shop.

- Industrial-quality scissors. Cheap models will not cut the cloth cleanly and will make a mess.

- Small plastic mixing container that will hold 3 ounces of liquid. I use a graduated paint mixing cup.

- Supply of 1/2-inch-wide cheap paint brushes.

- 5 cc pharmaceutical syringe to measure MEKP-9. Available at any pharmacy.

- 1-inch-wide 3M painter’s tape.

Have a website login already? Log in and start reading now.

Never created a website login before? Find your Customer Number (it’s on your mailing label) and register here.

Still have questions? Contact us here.

Mr. Bradley is a retired mechanical engineer with 34 years’ experience designing oil field pressure equipment and subsea pressure vessels. He is an instrument-rated private pilot with 700 hours in four different aircraft. Mr. Bradley owns a restored 1968 Cessna 172I. He is a certificated A&P mechanic with 10 years’ experience. AP3447020, EAA #1019569, AOPA #06229440.