By Jack Boyd

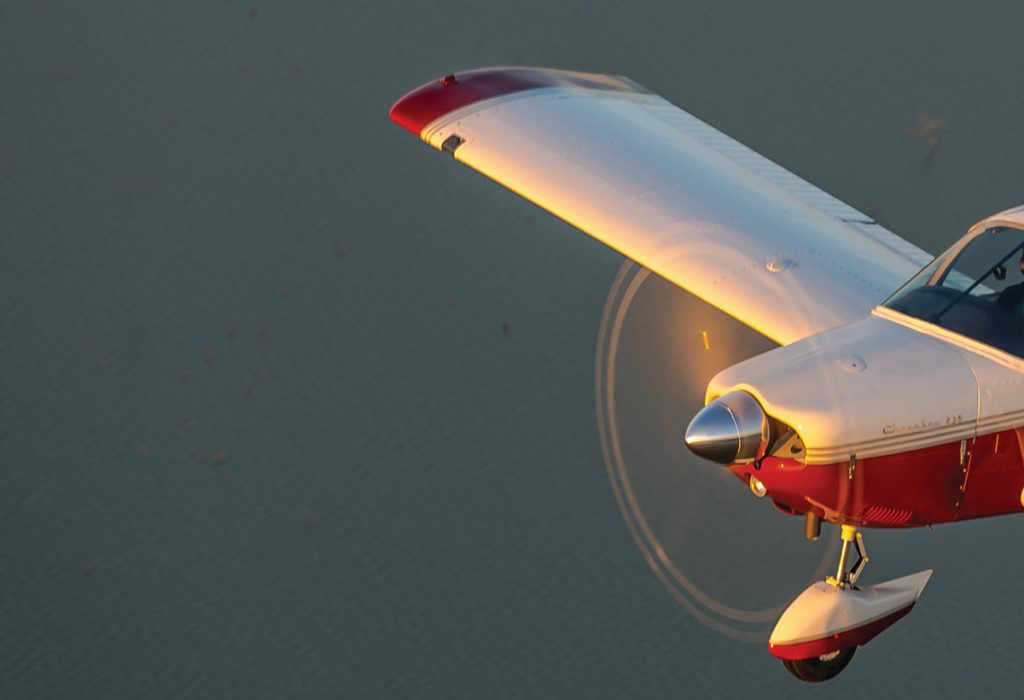

Could a tiny nick on a propeller blade cause an airplane accident? The simple answer is Yes! The propeller undergoes extreme stress while spinning, and even a tiny nick or chip could mean catastrophic failure at the worst possible time. Typically, a small nick or chip can develop into a crack.

The preflight inspection of one of our aircraft revealed this nick on one of the blades. The A&P smoothed out the damage to prevent it from becoming a dangerous crack. It only took a few minutes.

Takeaway

Inspect both sides of each propeller blade for nicks and chips by pinching your thumb and forefinger and running the full length along both edges. Start near the propeller hub and work outward to the tip. Immediately report any abnormalities to a licensed mechanic.

Fly safe friends.

Jack Boyd, ATP, CFII, MEI, DPE, is the president of Gold Standard Aviation flight training center. He is currently an FAA Designated Pilot Examiner and a former international airline pilot with a wealth of aviation real-world experience in high-density airspace environments.