By Craig Barnett

Much has been written about the process of stripping and applying paint to aircraft. However, a new paint job takes a lot of thoughtful planning and research before you hand your aircraft keys to your selected paint shop. Taking the time to prepare for your upcoming paint job will go a long way to ensuring that you select the best paint shop for your needs, the perfect paint scheme design, and a detailed understanding of the cost before beginning the actual paint work.

Painting your aircraft is one of the largest investments you’ll make in your aircraft. Quality paint is important to protect your valuable airframe. As your old paint deteriorates, new paint is not only aesthetically appealing, but also an essential maintenance item.

Preparing for a paint job involves two tracks, which can proceed simultaneously. One track is to identify potential shops to accomplish the work, obtain quotations, select the shop that best meets your needs, and secure a spot on their schedule. The other track is to work on the paint scheme design and color selection. The two tracks intertwine. For example, the final quotations from shops can only be provided once your paint scheme design is finalized, as that determines the materials and time required to accomplish the project. Similarly, different styles and the complexity of your paint scheme may require specific skills that influence your choice of paint shop.

Selecting a Paint Shop

There are approximately 170 paints shops around the U.S., which means there are likely several alternatives near you. As an aircraft owner, you can cast a wide net when exploring potential shops. Consider your aircraft speed and range, as well as the cost of dropping it off and picking it up from the paint shop. This can add significantly to the cost of the paint job. Flying the average four-seater, fixed-gear aircraft from your home base in North Carolina to a shop in Arizona or California isn’t usually practical. Figure out a practical distance based on speed and range and start by seeking shops within that radius of your home base. Keep in mind, not all paint work is perfect, and if you need warranty work, you will be spending a lot of additional time and money to get service if you choose a distant shop.

Not all shops cater to general aviation. Some specialize in small corporate aircraft, some in large corporate aircraft, and others in heavy jets. Weed these out to avoid wasting time. Shops catering to larger aircraft still have the same overhead when painting smaller aircraft, so if they do choose to quote your project, it’s likely that they will be very expensive.

Quotations will vary greatly. The work is labor intensive and typically includes significant hangar space and equipment. Shops in areas with high labor rates and rents will be more expensive than shops located at smaller, out-of-the-way airports.

Verify that your paint shop is using the best aviation products. Aerospace paints are different than automotive paints. They’re designed for our operating environment. High flexibility resists high vibration levels. Aerospace paints resist thermodynamic stresses from rapid temperature changes. They’re also tested for resistance to the unique fluids used in aviation, such as the blue dyes in avgas.

Your selected paint shop should have a properly designed and sealed paint booth with good air flow and environmental controls. Incoming air should be filtered to remove all particulate, as tiny dust or pollen particles can easily ruin a paint job. Booths should have good crossflow or downdraft ventilation. Only a portion of the atomized paint ends up on the aircraft. Good air handling removes excess atomized airborne paint, reducing the chance of it ending up on unintended parts of the aircraft as tiny overspray droplets.

Paint shops also need to be environmentally responsible. They need to have a system in place to legally and properly dispose of the residues of chemical strippers used to remove old paint, and filters to remove production residue to ensure they are not polluting the atmosphere. The last thing you need is for the EPA to padlock a paint shop with your aircraft in the paint booth.

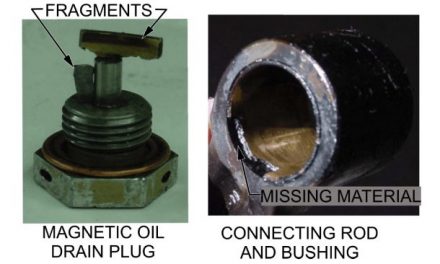

It’s useful to meet shop owners and let them see your aircraft during the quotation process. They will frequently see issues you may not, such as corrosion, hidden damage and failing composite components that will all add to the cost of the project. Similarly, you want to see their facility and meet their staff. Pay particular attention to the painter and the layout artist responsible for laying out your paint scheme design. It’s best if they have been with the shop a while and are knowledgeable and experienced. Make sure there is an A&P within the shop or on call to sign off on the final assembly and prepare the appropriate and detailed logbook entries at the end of the project.

Obtain references independently. Don’t rely only on references provided by the paint shop. Look beyond those to find other owners who have used the shops you’re considering. Try to see aircraft that have been painted by paint shops under consideration. Take a close look at the details, like the edges of stripes, the accuracy of points, the paint scheme layout and the smoothness and glossiness of the finished surface. Look for evidence of overspray, poor masking of unpainted areas, and other blemishes. Look out for paint runs, dry dull finishes, blotchy colors, and orange peel finishes. Avoid being influenced by sales and marketing hype. Most paint shops are low margin businesses; what counts is the outcome of the finished product.

When requesting a quote, be sure it includes a complete strip and paint. Make sure all removable parts, like control surfaces, cowling, wing tips, and inspection panels are removed during painting. A paint job should include replacement of old screws with new stainless-steel hardware that should remain unpainted, and all new screws should include nylon washers to avoid damage to the paint. Throughout the process, you’re looking to weed out shops that cut corners, use inferior materials, speed through the paint process, and frequently upcharge during the process by not fully disclosing all work beforehand. This means that the lowest quote isn’t always the best quote. Quality takes more work and the best materials and, as a result, it costs more. But a quality paint job will give you many more years of enjoying a new glossy finish and will positively impact the value of your aircraft.

Designing a Paint Scheme

Designing your paint scheme is a process that should be started as soon as you decide your aircraft needs new paint. Owners take a variety of approaches, from opting for a duplicate of a new model’s design to designing their own custom design to working with a professional design company such as my company, Scheme Designers (schemedesigners.com).

At the outset, understanding your tastes and styles is important. This involves spending a lot of time online looking at photos of the same or similar aircraft, and wandering around airports seeing what attracts your attention. My favorite website for research is airliners.net, which allows you to search hundreds of juried photos of aircraft like yours. Save ideas you find interesting to a unique folder. Take photos at the airport and add that to your saved favorites. Once you have accumulated a large array of photos, work your way through your collection, isolating your favorite ideas.

The goal of research is not to copy someone else’s design, but to understand your design approach. It isn’t a good idea to copy a design without permission. Often, designs that really catch your eye are professionally designed and copyrighted. The last thing you need is for your new paint job to become a liability when the owner of a copyrighted design decides to enforce their rights. More than a few owners have had to spend money to settle a copyright claim or repaint their aircraft to satisfy an infringement. Be aware that some manufacturers, like Cirrus, enforce their copyright on their factory new schemes, so automatically defaulting to a new factory scheme is not always the best solution. If you really want to copy someone else’s design, ask for permission first.

In determining your tastes, you need to explore your design style. What do you find appealing? Straight lines or curvy lines? Complex designs or simple ones? Edgy angular design or flowing design? An overall solid base color or a two-tone split base color? Solid or metallic/pearl colors? Keep in mind that the design choices you make have a direct impact on the cost of the project. As you make your choices, always consider cost implications. Speak to your paint shop or designer to understand the impact on the bottom line.

A basic quote from a paint shop is for two solid color stripes on a white base. As you add options, the price will increase from that basic quote. Don’t rely on the basic quote as your final price. Make sure you share your final design with your paint shop to obtain a final quote before you drop off your aircraft.

Most paint schemes have three to four colors. Every color you add will add to the cost of the paint job. Each additional color adds materials, layout, painting, and drying time, as well as additional overhead and labor costs. Metallic and pearl colors may look better but are more expensive and often require an additional application coat.

Split bases can add $1,000 to $2,500 to the cost of painting. Split bases often have more ramp appeal and presence and make aircraft look sleeker and faster. A dark lower split base also has the advantage of hiding the soot and oil that accumulates on the underside of a single engine aircraft fuselage, allowing longer times between washes.

The more complex your design, the longer it takes to lay out. A complex design can add days to the paint process, resulting in significant overhead and labor costs being added to your paint job. Very complex paint jobs are often highly personalized, which may impact the value of your aircraft.

A paint scheme design with colors separated by your base color can be laid out in its entirety prior to any colors being painted. If your paint scheme includes areas of touching colors, it requires each color to be independently laid out before being painted. This adds time and overhead to the project, raising the cost of painting.

When starting a paint scheme design, it’s essential to use accurate drawings of your aircraft. This should include modifications such as aftermarket wing tips, cowlings, and wheel pants. The drawings should also show the aircraft in the ground attitude — the way you normally see it.

Design is a process. You never know how long it’s going to take or how many iterations you’ll need before arriving at the perfect solution. As a professional aircraft paint scheme design service, we work under a flat fee that includes unlimited design, color, and layout changes and time. We don’t want a customer to worry that each small change will add cost. Rather, we want a client to make as many changes as needed to perfect their design choices and to take as long as necessary to consider their design choices before making a final selection. Don’t rush the process and don’t compromise on your choices. This is your opportunity to make your aircraft look perfect and brand new again.

When creating your design, consider your registration number, particularly if you plan on a 12-inch-high number. 12-inch-high numbers are required on certified aircraft newer than 30 years old. If you regularly fly any aircraft into or through the Washington D.C. area or through an ADIZ, you’re required to have 12-inch registration numbers. For only occasional trips, you can opt to apply temporary 12-inch numbers. These need to be located horizontally between the wing trailing edge and the horizontal tail leading edge, or on the vertical tail.

Antique aircraft older than 30 years-old required only 2-inch-high registration numbers. Registration numbers, especially 12-inch- high ones, need to be designed as a part of the paint scheme design. Squeezing a registration number into a paint scheme after the design is completed will typically look forced and may well ruin a design. Style the number and explore angling the characters aft and applying outlines and shadows to make them aesthetically appealing.

Be sure to check what brand of paint your paint shop prefers. You can obtain a color chart from the paint shop, from your designer, or directly from the paint manufacturer. Choose and specify specific colors from the chart and let the paint shop know your choices well ahead of time so paint can be mixed or purchased in advance. Ingredients in some colors may have long lead times. Each paint brand has unique processes and application techniques. Avoid requiring a paint brand that your paint shop hasn’t used before because your aircraft will be their test vehicle.

If you design your own paint scheme, provide as much detail as possible to the paint shop. Ideally, they benefit from detailed dimensioned or scaled drawings, written instructions, and specific color choices. When we complete a project, we engineer it to produce a detailed set of layout drawings to 1/8-inch and written specifications giving the paint shop a complete visual and dimensional roadmap to applying the paint scheme. Without the necessary detail, there is no way to ensure that the layout artist will accomplish your vision to your satisfaction. Some layout artists can work from just photographs or a reasonable sketch, but that leaves a lot of interpretation. In essence, you’re giving up design ownership to the layout artist with no guarantee of the outcome.

Once your design is completed, be sure to share it with your paint shop and let the shop revise your quote accordingly. Added extras may result in some sticker shock, but, if necessary, preplanning will allow you time to implement revisions to reduce the cost.

There is a lot to learn when repainting your aircraft. Usually, owners are finally educated when they pick up their aircraft. By then it’s too late. Take your time to do your research and planning. Speak to experts to solicit help and advice. You’ll avoid the many pitfalls and issues commonly encountered and maximize the pleasure of picking up your beautiful, renewed aircraft.

Craig Barnett is the Founder and CEO of Scheme Designers, Inc. His company is responsible for over 16,000 unique paint scheme designs in over 150 countries. He has designed numerous airline livery and corporate fleets worldwide and provides design services to the majority of general aviation manufacturers. More than half of all design projects are for individual owners of homebuilt and certified general aviation aircraft. Craig has been a pilot for over 40 years and has owned an aircraft for most of that time. He is a commercial pilot with an IFR and multi-engine rating.