By Rocky Landsverk

There’s an old adage that people with money can more easily make money. Equally true is people without money often spend more money in the long run by not “doing it right” in the first place.

That is especially true in a plane restoration. As cover story plane owner Greg Piehl stated during the Comanche restoration series articles, if you have to stop the restoration for a while to save money to do something “right,” then that’s a better decision than moving forward and needing to reopen that area of the plane in the future.

Fred Fischer tried to utilize the “it’s cheaper to do it once” motto during the restoration of his 1976 PA-32R-300 Cherokee Lance, which wound up costing far more than he expected, in large part because he didn’t want to cut corners, then have to fix those shorcuts in a year or two. “If you’re going to do it, do it right, even if you have to wait a couple years until it’s financially feasible,” Fischer said. “Otherwise, you’re going to be paying twice to open things back up again.”

For example, Fischer said, “You’ve gotten this far. Do you still want 40-year-old circuit breakers in your airplane?”

Fischer’s advice is simple, but it’s not easy to hear and it’s even harder to live by. Other Piper owners who went through major upgrades have told us the same thing many times — plan on far more time and expense than you think you’ll need when you start the renovation. “I just didn’t budget as much as I should have,” Fischer said.

Most of this work was done by ProAv Aircraft Services (proavaircraft.com), located at Harry Clever Field (KPHD) in New Philadelphia, Ohio. Eric Hubbard is the president and general manager.

Start to Finish

Fischer started flying young, then quit for a while, then restarted. “I started flying when I was 16, and as of about four years ago, I hadn’t flown for 22 years,” Fischer said. “A friend of mine in the Florida Keys started getting on me [to get my license current again]. So, I renewed my third-class medical, then got checked out in a 172 that I rented.”

He then started looking for a plane to buy himself and kept an eye on this Lance. He said he had about 60 hours in Cherokees and Saratogas, “so it wasn’t like I didn’t have complex time.”

Fischer bought the plane in the spring of 2020 and started an overhaul that took a year and was led by his A&P Eric Hubbard. Because his strategy was doing it right the first time, Fischer told Hubbard, “If I’m going to do this, let’s just go all-Garmin.”

A plane restoration is long and expensive enough as it is, even without making decisions like “let’s go all-Garmin.” Fischer’s point is that even if you can’t afford Garmin, you should at least realize that the plane should be torn down and significantly restored, including corrosion fixes, new cables, etc., while it’s torn apart for other things.

“In hindsight, what I now believe is that anybody who buys a plane [for a restoration], I think you want to tear that thing down pretty good. My paint and interior were in pretty good shape, but while they’re doing all of these improvements, you’re going to keep coming across little things, and they add up.”

For instance, with his plane, Fischer said there were mud daubers in the wingtips. “It didn’t affect the magnetic compass they were installing, but had we not done the glass panel, I don’t know that we would have seen them. I had already gone through an annual and it was not something you would look for.”

During that work on his wingtips, Fischer again told ProAv to continue doing it right and doing it well. “I got my electric trim back, but guess what, two pulleys had flat spots on them, which would have never shown up unless we stripped all the cable out, because they had to make the cable loose to readjust it to put the two new servos in,” he said, referring to servos that came with some new Garmin equipment.

Quotes in the photo captions are from Fischer.

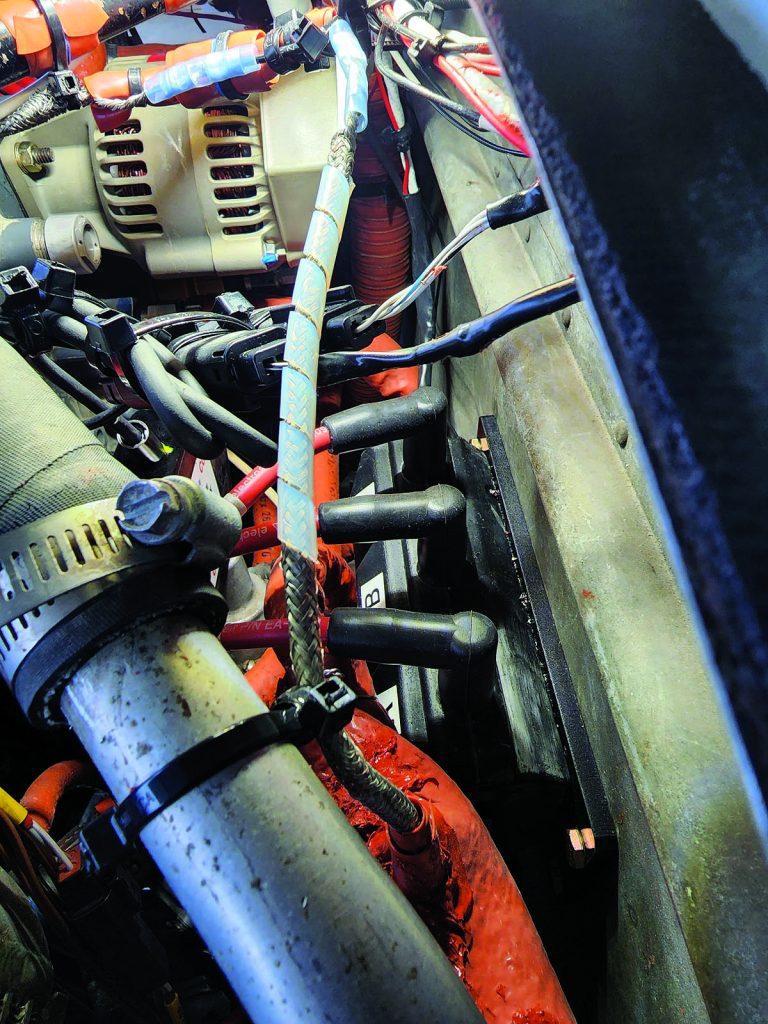

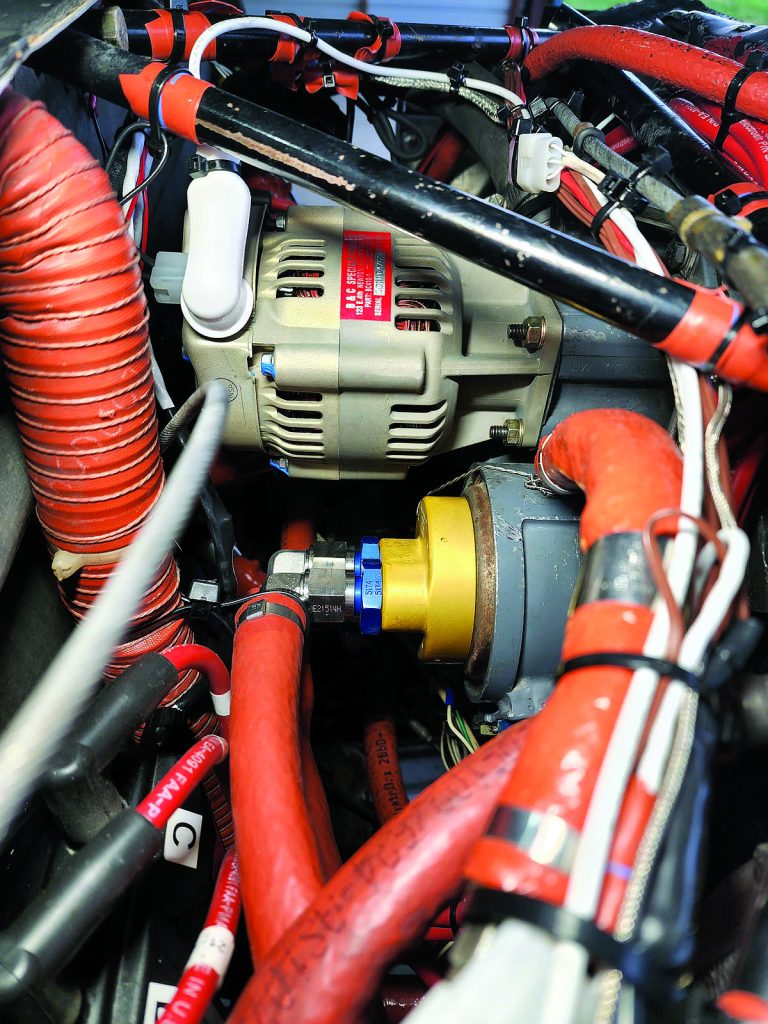

Before and after the Electroair upgrade moved the oil filter. In the Before picture, “You can see the oil filter, the white thing with writing on it. The new alternator was to go right beside that, so again that’s an example of another $500 for the kit [to move the oil filter] and a couple hundred bucks for the hoses.” In the After picture, “This is where the oil filter wound up, lower on the firewall.”

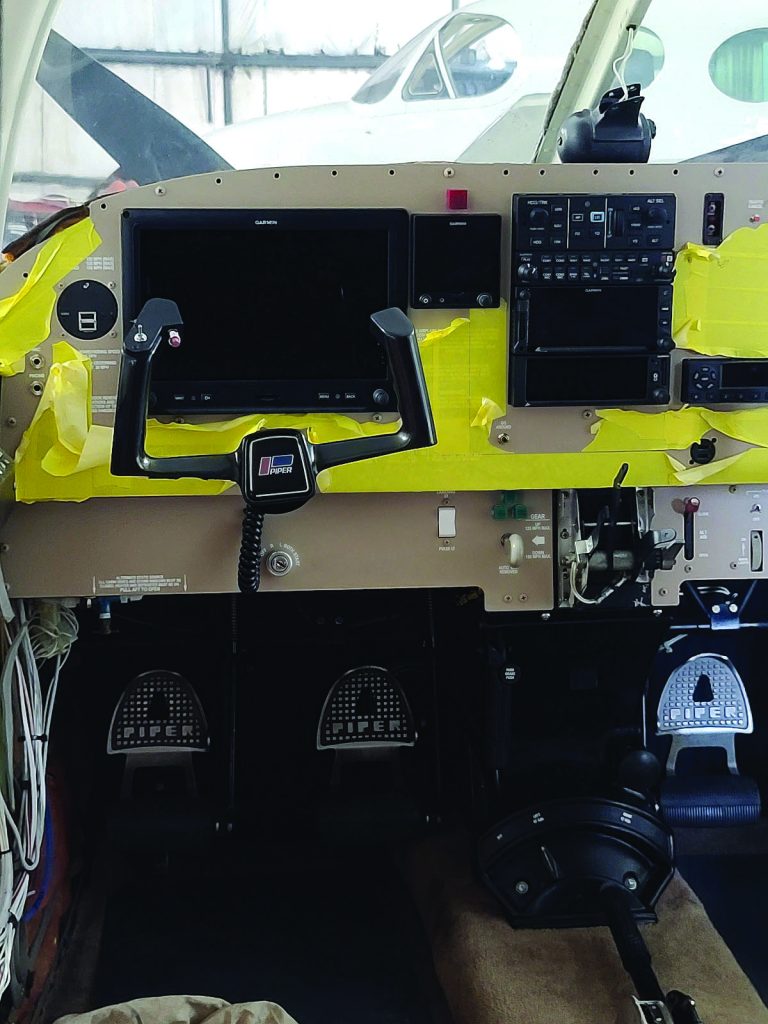

The panel is different than almost any other Piper you’ll find and looks especially cool when the LED lights are on. On the left side of the panel is a Garmin G3X primary flight display, with the smaller G5 (DG/HSI) next to it. On the right is the stack including the Garmin GFC500 autopilot, GMA 345 Audio Panel, GTN 650xi nav/com/VOR, GNC 355 nav/com, and to the right the GTX 345 ADS-B In and Out transponder. The autopilot isn’t in a typical location for a vintage Piper, but Fischer said “that’s where most of the jets have them, and it made sense to me that I could still be looking out the window and not have to look down when I’m engaging it or changing it.”

Coming next month

An intensive look at the Electroair upgrade, including a review after installation of the STC approved dual-magneto system.